Resonant laser cooling brings gallium arsenide down to 4 K

Copenhagen, Denmark--Researchers at the Niels Bohr Institute have developed what they call a new method for laser-cooling of semiconductor membranes.1 Using the new method, the researchers have resonantly dampened the fluctuations of a 160-nm-thick gallium arsenide photonic-crystal membrane to cool it to -269 °C (about 4 K). (A nonresonant method of laser cooling a 2-μm-thick gallium arsenide membrane to 165 K was previously shown by researchers at the University of New Mexico and the Universita di Pisà in Italy).

“In experiments, we have succeeded in achieving a new and efficient cooling of a solid material by using lasers,” says Koji Usami, an associate professor at the Niels Bohr Institute. "We have produced a semiconductor membrane with a thickness of 160 nm and an unprecedented surface area of 1 by 1 millimeter. In the experiments, we let the membrane interact with the laser light in such a way that its mechanical movements affected the light that hit it. We carefully examined the physics and discovered that a certain oscillation mode of the membrane cooled from room temperature down to -269 °C, which was a result of the complex and fascinating interplay between the movement of the membrane, the properties of the semiconductor and the optical resonances."

“For some time, we have wanted to examine how far you can extend the limits of quantum mechanics -- does it also apply to macroscopic materials? It would mean entirely new possibilities for what is called optomechanics, which is the interaction between optical radiation, that is light, and a mechanical motion,” adds Professor Eugene Polzik, head of the Center of Excellence Quantop at the Niels Bohr Institute at the University of Copenhagen.

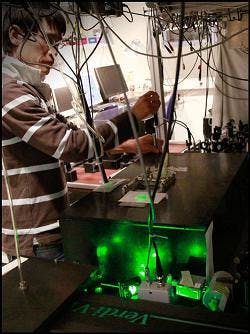

The photonic-crystal membrane is made of gallium arsenide. Laser light strikes the nanomembrane in a vacuum chamber; a separate mirror forms a resonator. Some of the light is absorbed by the membrane and releases free electrons, which decay and heat the membrane, causing thermal expansion. In this way the distance between the membrane and the mirror is constantly changed in the form of a fluctuation. This change in distance occurs at the resonant frequency and removes thermal energy from the mirror.

"The paradox is that even though the membrane as a whole is getting a little bit warmer, the membrane is cooled at a certain oscillation and the cooling can be controlled with laser light," says Usami. "So it is cooling by warming."

“The potential of optomechanics could, for example, pave the way for cooling components in quantum computers. Efficient cooling of mechanical fluctuations of semiconducting nanomembranes by means of light could also lead to the development of new sensors for electric current and mechanical forces. Such cooling in some cases could replace expensive cryogenic cooling, which is used today and could result in extremely sensitive sensors that are only limited by quantum fluctuations,” says Polzik.

REFERENCE:

1. K. Usami et al., Nature Physics, Published online 22 January 2012; doi:10.1038/nphys2196.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.