High-speed cameras enable us to understand the dynamics of processes including combustion, particle image velocimetry (PIV), and ballistics. But polarization can play a key role in revealing the internal stress mechanisms of the materials in question. While conventional polarization cameras typically use discrete optical filters to determine the retardation between the fast and slow axes for anisotropic materials, Photron (San Diego, CA) has developed its Crysta camera with a monolithic sensor that avoids the vibration/misalignment vulnerability of bulk optics.

The Crysta’s 1 Mpixel sensor includes a photonic crystal polarizer applied directly to the high-speed sensor with clusters of four 20 µm square pixels forming a “polarization pixel,” each having a different polarization axis, offset 45˚ from its neighbor, at 0˚, 45˚, 90˚, and 135˚. This 2D polarization sensor architecture, coupled to its high-speed parallel read-out analog-to-digital (A/D) converters, enables the light-sensitive sensor to provide 7000 frames-per-second (fps) polarization images, and over 1 million fps at reduced resolution, including retardation, polarization axis, and conventional monochrome high-speed data from a single camera.

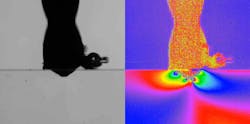

Given the direct correlation between birefringent retardation and the stress in materials, the Crysta lets users see how stress is formed in high-speed dynamic detail. For example, images recorded by the Crysta from drilling an acrylic block at 1000 fps show the birefringent stress distribution. Tests like these enable engineers to adjust the cutting and drilling processes to minimize stress and resultant defects in finished products. Reference: https://photron.com/crysta-polarization-high-speed-camera.