Currently, the only means of producing 3D-printed or additive-manufacturing (AM)-based components consisting of more than one material is through extrusion of multiple materials using different nozzles, through hybrid processes such as a combination of single-wavelength vat polymerization combined with extrusion or injection processes, or by changing the vat materials and/or source wavelength during the print process (midprint).

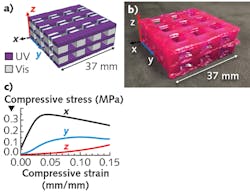

Recognizing the need to advance AM towards the creation of multimaterial components in one process step, scientists at the University of Washington (Seattle, WA) and the University of Wisconsin (Madison, WI) have developed a multiwavelength vat-polymerization process that takes advantage of the wavelength-specific cure properties of certain chemicals. By projecting two or more wavelengths of light (using spatial digital light projection methods) into a vat filled with a mixture of resins, acrylates, epoxies, polymers, or other organic and inorganic liquid chemicals that cure with different wavelengths (in the visible, ultraviolet, or infrared), a 3D rendering of a multimaterial object can be produced in one process step. Reference: J. J. Schwartz and A. J. Boydston, Nat. Commun., 10, 791 (Feb. 15, 2019).