Today's fiber-optic communications networks typically operate in the 1550 nm spectral window and use erbium-doped fiber amplifiers (EDFAs) to extend communication distances or boost power for wavelength-division multiplexed (WDM) technology.

But to take advantage of new spectral windows for future communications bandwidth needs and amplify signals from hollow-core photonic bandgap fibers in the 1600–1750 nm spectral region not served by EDFA technology, scientists in the Fiber Optics Research Center of the Russian Academy of Sciences (Moscow, Russia) have developed a bismuth (Bi)-doped optical fiber amplifier pumped by commercially available 1550 nm laser diodes that operates from 1640 to 1770 nm.1

Bi-doped MCVD fibers

Although thulium (Tm)-doped fiber amplifiers (TDFAs) can operate in the 1700 nm (and up to 1900 nm) window, low efficiency and intense amplified spontaneous emission (ASE) must be suppressed through a variety of special co-doping and home-built ASE filter technologies, making it difficult to use TDFAs for the 1700 nm window.

Alternatively, Bi-doped germanosilicate fibers provide amplification in the 1700 nm band and the research team has developed a 1700 nm optical amplifier by developing special Bi-doped optical fiber with high germania content. To obtain the best gain profile, several optical fibers with various Bi-doped core concentrations were fabricated using the modified chemical vapor deposition (MCVD) method.

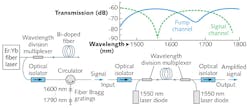

The Bi-doped fiber amplifier (BDFA) has 125-μm cladding, 2-μm-core-diameter Bi-doped fibers of varying dopant concentration, and is core-pumped bidirectionally by two 150 mW, 1550 nm laser diodes (see figure). To measure performance of the BDFA, a home-built multiple-wavelength light source was constructed from a superluminescent Bi-doped fiber source and highly reflective fiber Bragg gratings (FBGs) to create evenly spaced (15 nm apart) spectral lines from 1615 to 1795 nm.

1700 nm performance

Based on measurements of various BDFA performance parameters, a Bi concentration of 0.015–0.02 weight % was the optimal value for maximum optical gain. The optical amplifier with a 50 m Bi-doped fiber provided a maximum gain of 23 dB at 1710 nm with a 3 dB bandwidth of 40 nm, a gain efficiency of 0.1 dB/mW, and a minimum noise figure of approximately 7 dB. The 3 dB gain bandwidth and efficiency of BDFA were better when compared to the TDFA.

"An important problem is the development of optical fiber amplifiers for novel spectral regions, where optical losses of telecommunication fibers have a value less than 0.4 dB/km," says professor Evgeny Dianov, scientific director of the Fiber Optics Research Center of the Russian Academy of Sciences. "This would make it possible to use the extended spectral region for information transmission in high-speed fiber-optic systems. The development of this amplifier is one of the first main stages in this direction."

Dianov adds, "In this pursuit, it is desirable to create broadband optical amplifiers with gain bandwidth of more than 100 nm. This would be a new breakthrough in the development of optical fiber communication systems using these amplifiers and active fibers."

REFERENCE

1. S. V. Firstov et al., Sci. Rep. online, 6, 28939 (2016); doi:10.1038/srep28939.