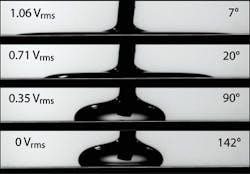

In electrowetting, an applied voltage changes the wetting angle of a liquid; the phenomenon is used in liquid lenses and, with pigmented fluids, in liquid displays. Now, researchers at the Massachusetts Institute of Technology Lincoln Laboratory (Lexington, MA) and Tufts University (Medford, MA) have created a new class of electrowetting systems that produces larger contact-angle changes at much lower voltages—easing the development of portable electrowetting devices. In the new approach, lipid bilayers on hafnium oxide films become reversibly wettable dielectrics that change contact angle from 140º to less than 10º using less than 1 V.

A 3 to 4 mm water droplet submerged in dodecane with 0.1% sorbitan trioleate contacted the hafnium oxide surface; an applied sine-wave voltage at 300 Hz was applied across the drop to change the wetting angle. Ingrid Guha, one of the researchers, notes that preliminary reliability testing was performed on the lipid bilayer (on the order of thousands of cycles over the course of a couple days at 75% duty cycle) and the bilayer remained completely stable, maintaining full electrowetting reversibility. “At normal operating voltages,” she says, “we have not seen any failures or instability in operation that might indicate changes in the dielectric.”

Contact Ingrid Guha at [email protected].