When used in a biosensing application, a polymer micromachined Fabry-Perot interferometer (μFPI) developed by researchers at Louisiana Tech University (Ruston, LA) has an approximate 20X improvement in free-spectral range (FSR), 2X improvement in finesse, and 4X improvement in contrast of optical transducing signals compared to a traditional semiconductor-based μFPI.

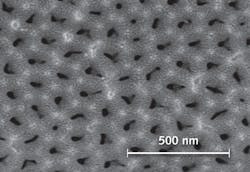

Traditional μFPI biochemical sensors fabricated from silicon, polysilicon, or other semiconductor thin films and operated using lasers suffer from limited sensing areas, limited depth penetration of the sensing light, and limited intensity of the transducing signal due to light losses at the FPI plate/air interface. The Louisiana Tech biosensor instead uses a polydimethylsilicone (PDMS) microfluidic chip bonded to a gold-coated nanopore layer inside a μFPI cavity and a lower-cost broadband white-light source. The 50 nm diameter nanopores increase the sensing area compared to traditional devices and allow the source to penetrate to a depth of 3 μm within the structure. Reflected light is analyzed to observe interference-fringe shifts corresponding to refractive-index changes caused by the substance being sensed. The nanopore structures could be modified to possibly enable single-molecule sensing. Contact Long Que at[email protected].

More Laser Focus World Current Issue Articles

More Laser Focus World Archives Issue Articles