Physicists at the National Institute of Standards and Technology (NIST) and the University of Colorado (both in Boulder, CO) have used common electronics to build a laser that pulses 100 times faster than conventional ultrafast lasers. The advance could extend the benefits of ultrafast science to new applications such as imaging of biological materials in real time.1

The technology for making electro-optic lasers has been around for five decades, and the idea seems alluringly simple. But until now researchers have been unable to electronically switch light to make ultrafast pulses and eliminate electronic noise, or interference. The NIST scientists developed a filtering method to reduce the heat-induced interference that otherwise would ruin the consistency of electronically synthesized light. The electronic signals are stabilized and filtered as they bounce back and forth inside an aluminum cavity; fixed waves emerge at the strongest frequencies and block or filter out other frequencies.

A conventional source of ultrafast light is an optical frequency comb, often created with sophisticated mode-locked lasers, which form pulses from many different frequencies of light waves that overlap, creating links between optical and microwave frequencies. Interoperation of optical and microwave signals powers the latest advances in communications, timekeeping, and quantum sensing systems.

In contrast, NIST's new electro-optic laser imposes microwave electronic vibrations on a continuous-wave laser operating at optical frequencies, effectively carving pulses into the light. The new electro-optic laser produces pulses every 100 ps rather than the usual ~10 ns.

"Chemical and biological imaging is a good example of the applications for this type of laser," says project leader Scott Papp. "Probing biological samples with ultrafast pulses provides both imaging and chemical makeup information. Using our technology, this kind of imaging could happen dramatically faster. So, hyperspectral imaging that currently takes a minute could happen in real time."

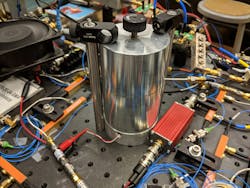

To form the electro-optic laser, NIST researchers start with an infrared continuous-wave laser and create pulses with an oscillator stabilized by the cavity, which provides the equivalent of a memory to ensure all the pulses are identical. The laser produces optical pulses at a microwave rate, and each pulse is directed through a microchip waveguide structure to generate many more colors in the frequency comb. The laser was constructed using commercial telecommunications and microwave components, making the system very reliable. The combination of reliability and accuracy makes electro-optic combs attractive for long-term measurements of optical clock networks or communications or sensor systems in which data needs to be acquired faster than is currently possible.

Source: https://www.nist.gov/news-events/news/2018/09/nists-electro-optic-laser-pulses-100-times-faster-usual-ultrafast-light

REFERENCE:

1. David R. Carlson et al., Science (2018); doi: 10.1126/science.aat6451.