University of Luxembourg and electronics company TDK (Japan) scientists have improved a component that will enable solar cells to use more energy from the sun and increase photovoltaic optical-to-electrical conversion efficiency. The improvement concerns a conductive oxide film that has improved transparency in the infrared region. Similar attempts had been made before, but this is the first time that these films are prepared by a one-step process and, at the same time, are stable in air.

RELATED ARTICLE: New transparent conductive film method both cost-efficient and eco-friendly

"The films made at the University of Luxembourg have been exposed to air for one and half years and are still as conductive as when they were fresh prepared," says professor Susanne Siebentritt, head of the laboratory for photovoltaics at the University of Luxembourg. "It is a fantastic result, not only for solar cells, but also for a range of other technologies," she adds. Collaborators of this study were Matěj Hála, research associate in the laboratory for photovoltaics, and Shohei Fujii and Yukari Inoue, visiting scientists from TDK.

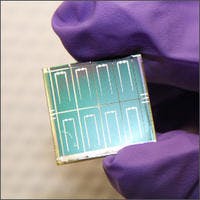

Transparent conductive oxides are used in any device combining electronics and light, like LEDs, solar cells, photodetectors, or even touch screens. They have the particularity to combine the properties of metals, which are the best electrical conductors known, with those of oxides, which usually are transparent but not conductive (like glass). In solar cells the film has to be conductive because it constitutes the upper electrode. At the same time it has to be transparent in order for sunlight to reach the layer underneath, where the current is formed.

The oxides forming this film can be made conductive by deliberately adding impurities. Zinc oxide with aluminum added is a widely used example. In this case, the aluminum adds free electrons to the zinc oxide which are responsible for the conductivity. However, these free electrons also absorb infrared light. That means that less sun energy can pass through.

The team of the University of Luxembourg and TDK has modified the process used to make the film in order to make pure zinc oxide more conductive. "Our multidisciplinary team, benefitting from the exchange of knowledge across countries, had the idea to add an additional component—another gas plasma—in the so called sputter process. This makes the material conductive even without aluminum," says Siebentritt.

This method enables to have fewer, but faster-moving free electrons. "With this result, the conductivity is similar to the one with aluminum, but it enables a much better transparency in the infrared region as less free electrons cause also less absorption. That makes solar cells more efficient," adds Hála. The research is published in Progress in Photovoltaics: Highly conductive ZnO films with high near infrared transparency.

SOURCE: University of Luxembourg; http://wwwen.uni.lu/universite/actualites/a_la_une/researchers_enable_solar_cells_to_use_more_sunlight