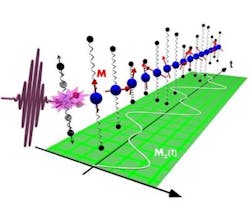

A team from Radboud University (Nijmegen, The Netherlands) and Taurida National University (Simferopol, Crimea) has developed a way to use sound to couple magnetism with light.1 In the technique, 100-fs pulses from an ultrafast laser trigger oscillations in the magnetic anisotropy of the dielectric iron borate (FeBO3).

Because a beam of light is in this case directly controlling magnetism, the new method could leapfrog current widespread efforts to create "spintronic" data storage devices intended to replace conventional hard disks.

Anharmonic

The laser pulses excite electrons in a medium to such an extent that the excited electron clouds push the atoms off, setting them in motion and launching a sound wave. The fact that the sound wave can effectively couple to the magnetization is well known, but, unexpectedly, the scientists found that the optically launched sound at a frequency f is accompanied by a response of the magnetization at the frequencies f, 2f, and 3f. Such a phenomenon is called anharmonicity. (Any pendulum becomes anharmonic when deviations from its equilibrium become large.)

"The fact that the laser-induced oscillations of the magnetization are anharmonic is very intriguing," says Alexey Kimel, associate professor and research group leader at Radboud University. "It means that the coupling of light with the magnetism is very effective and we are getting close to our dream—to record magnetic information with the help of light."

Source: http://www.alphagalileo.org/ViewItem.aspx?ItemId=140827&CultureCode=en

REFERENCE:

1. D. Afansleve et al., Physical Review Letters (2014); doi: http://dx.doi.org/10.1103/PhysRevLett.112.147403