Stockholm, Sweden--Midsummer, a supplier of production lines for manufacturing flexible thin-film copper indium gallium selenide (CIGS) solar cells, has developed a high-speed process for manufacturing of these cells using sputtering of all layers in the photovoltaic (PV) cell structure. By using sputtering in all processing steps, the process cycles in the manufacturing of solar cells can be shortened, the solar cells can be made cadmium (Cd)-free, and they can be made on stainless-steel substrates suitable for flexible modules. The process is a dry, all-vacuum process.

Midsummer has made Cd-free CIGS cells with a 15.0% active-area efficiency across PV cells with a 225 cm2 area. The cells were made on stainless-steel substrates stamped out from 0.3-mm-thick conventional ferritic stainless steel. Even the buffer layer was sputtered (normally it is deposited with chemicals or by atomic-layer deposition). Also, the CIGS layers were sputtered from compound CIGS targets, resulting in a short cycle time (eliminating the need for selenizing the solar cells for several hours).

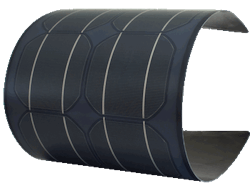

CIGS cells on stainless steel substrates are suitable not only for regular solar panels, but also for flexible, lightweight panels that can be used on membrane roofs, landfills, or other structures where traditional glass modules cannot be applied.

Midsummer's Duo sputtering tool system has a 5 MW annual CIGS solar-cell production capacity.