Greenbelt, MD--Researchers at NASA Goddard Space Center have created what appears to be an almost perfect light absorber functioning from the UV to the far-IR. Consisting of a forest of aligned multiwalled carbon nanotubes, the material absorbs 99.5% of the light in the UV and visible, dipping to 98% in the far-IR bands. The absorber could be especially valuable in space optical instruments, where even small reflections can cause detrimental ghosting and halos, and also where physical fragility of the absorber would not be a problem.

The researchers reported their findings at this year's SPIE Optics and Photonics conference (San Diego, CA; August 21-25, 2011). The team has since reconfirmed the material's absorption capabilities in additional testing, says John Hagopian, who is leading the effort involving ten Goddard technologists. "The reflectance tests showed that our team had extended by 50 times the range of the material's absorption capabilities," Hagopian adds. "No one else has achieved this milestone yet."

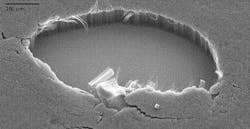

The team has grown the nanotubes on silicon, silicon nitride, titanium, and stainless steel, materials commonly used in space-based scientific instruments. (To grow carbon nanotubes, Goddard technologist Stephanie Getty applies a catalyst layer of iron to an underlayer on silicon, titanium, or other material. She then heats the material in an oven to 1382°F. While heating, the material is bathed in carbon-containing feedstock gas.)

The tests indicate that the nanotube material is especially useful for a variety of spaceflight applications where observing in multiple wavelength bands is important to scientific discovery. One such application is stray-light suppression.

If used in detectors and other instrument components, the technology would allow scientists to gather hard-to-obtain measurements of objects so distant in the universe that astronomers no longer can see them in visible light, or those in high-contrast areas, including exoplanets, Hagopian says.

Because the coating is an almost perfect blackbody emitter, it can help radiate heat away from IR-sensing instruments, notes Goddard engineer Jim Tuttle.