If a handheld spectrometer could be created that operated without the need for a spectral-scanning mechanism, its resulting simplicity and low cost would greatly expand its practical usefulness. Researchers from the Office National d’Etudes et de Recherches Aérospatiales (Palaiseau, France) and the Commissariat à l’Energie Atomique, Laboratoire d’Electronique et do Technologie de l’Information (Grenoble, France) have taken a giant step toward the realization of such a widely usable device by designing and building an infrared focal-plane array (IRFPA) containing a simple modification that turns it into a scanner-free Fourier-transform IR (FTIR) spectrometer.1

One previous design for a scanner-free FTIR spectrometer contains a Michelson interferometer with a tilted mirror and, at the image plane, an IRFPA; due to the complexity of the interferometer, however, the instrument is still expensive and heavy (20 kg or so).2 What the French researchers (one of whom, Nicholas Guérineau, also worked on the previous design) have done in their new design is incorporate an interferometer into the IRFPA.

A typical IRFPA, made up of mercury cadmium telluride (HgCdTe) detector elements fabricated on a cadmium zinc telluride (CdZnTe) substrate, is used in backside-illumination mode, for which the CdZnTe substrate is usually thinned to a few micrometers in thickness and serves as the window through which the test light enters the instrument. The French researchers instead polish (via etching) the CdZnTe substrate at an angle, turning it into a wedgeand thus an intrinsic Fizeau interferometer usable for FTIR spectroscopy. In fact, for one of their IRFPAs (which they term FTIR-FPAs), they have created a 10 mrad wedge with a zero thickness at one edge and thus a zero path difference that allows them to see the zero fringe at that edge.

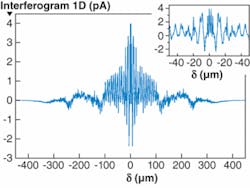

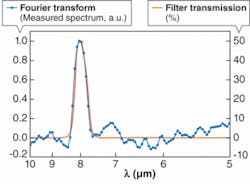

The researchers “symmetrize” the resulting one-dimensional interferogram obtained by the FTIR-FPA by duplicating the interferogram and flipping the duplicate to the other side of the zero point of the plot (see Fig. 1). Taking the Fourier transform of this symmetrized interferogram reproduces the IR spectrum of the source. For example, light from a blackbody source passed through a bandpass interference filter was measured by the device, resulting in an IR spectrum whose peak closely matched that of the bandpass filter (see Fig. 2).Like other HgCdTe-based IRFPAs, the FTIR spectrometer created by the French researchers is cryogenically cooled. Because the FTIR-FPA itself is so compact, however, cryogenic cooling won’t prevent portability of a practical device. “The next generation of FTIR-FPAs will be integrated in a compact integrated detector dewar cooler assembly with a Stirling-cycle rotary (or linear) cooler,” says Guérineau.

Such portability will enable wider use and, indeed, even casual use of FTIR spectrometers. For his group’s device, Guérineau envisions applications such as engine-gas monitoring (sensing multiple gases such as oxygen, carbon monoxide, carbon dioxide, and others) and remote sensing of chemical agents such as nitrogen oxides or sulfur compounds, either in industrial or military contexts.

REFERENCES

1. S. Rommeluère et al., Optics Lett. 32, 1062 (May 15, 2008).

2. N. Guérineau et al., Proc. SPIE 5249, 441 (2003).