Once relegated primarily to the lab-based tabletops of scientific researchers, near-infrared (NIR) spectroscopy has become a well-regarded process-control tool for industrial applications. Ongoing efforts to make NIR instrumentation more robust, affordable, and user-friendly have enabled the unique materials-analysis capabilities of this technology to move out of the laboratory and into cleanrooms, factories, and even field-based environments. In fact, as the instrumentation has become more robust and user friendly, it has found a growing customer base in a spectrum of industries, including dairy products and other beverages, feed and grain, meat and sausage, pulp and paper, forestry, cement, cosmetics, ink, oils, soil, pharmaceuticals, and recycling.

In recent years, advances in hardware and software have made NIR spectrometers even more streamlined and rugged, providing high-resolution spectra in less than a second under even the harshest conditions. Several companies now offer handheld “microspectrometers” designed for point-of-use, field-based applications (see Fig. 1). Many of these systems take a modular platform approach that allows the creation of application-specific tools, giving users the ability to “plug and play” the desired application simply by switching software programs.

“There is a general trend in instrumentation toward smaller, field-portable ‘answer boxes’ in which the guts of the instrument may be quite sophisticated and the internal analysis may be complex, but the users are only looking for a fast, easy answer,” said Greg Smolka, vice president of sales and marketing at Axsun (Billerica, MA). “The beauty of this is that people have been using Fourier-transform NIR for years and they know the technique well but have been limited in their deployment outside the lab environment either because the high-performance FT-NIRs are expensive and not fieldable, or because simpler NIR spectrometers don’t have the performance capabilities required for many applications.”

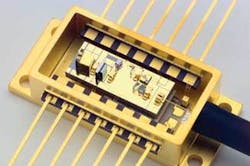

New optical technologies—many developed during the telecom boom—are helping to address these needs. Axsun is one of several companies finding new opportunities for optical technologies originally designed for telecom applications. Founded in 1999 as a pure-play telecom company, Axsun has since taken its tunable diode laser and proprietary MEMS technology and developed a miniaturized 14-pin butterfly-package platform that can be reconfigured for a number of materials-analysis applications simply by loading a different script or library (see Fig. 2). The result is a compact, rugged, battery-powered NIR (1350-1800 nm) spectrometer that offers the performance of a lab-based FT-NIR system but at a cost of only $20,000, compared to $80,000 for the cart-based systems that in recent years have made their way into various industrial environments.Carpet recycling?

These advances are enabling NIR technology to move not only out of the lab but into truly mobile field-based situations, such as carpet and plastics recycling. With the continued high price of crude oil, producers of carpeting and various plastic products have been looking for alternative sources of the polymers that go into these products. In carpet recycling, for example, companies like Shaw and DuPont have recognized that by better assessing the raw materials available in reclaimed carpet, such as Nylon 6, Nylon 66, and polypropylene, they can more efficiently and cost-effectively extract these materials for reuse. The situation is similar in plastics recycling, where “state of the art” materials analysis is still often a Bic lighter and a sophisticated nose, according to Smolka.

This is where NIR spectroscopy comes in. The technology is not new to the recycling world, but having a low-cost, handheld, point-of-use system that can distinguish between, say, Nylon 6, Nylon 66, and polypropylene and assess the amount of each in a carpet sample. Each type of fiber produces a unique spectral signature identifiable using NIR spectroscopy, regardless of color or textural differences.

“Part of the reason that carpet recycling is gaining interest right now is that there is becoming an outlet for used carpet,” Smolka said. “It is great to recycle, but what do you do with it? Shaw Flooring, the largest carpet manufacturer in the United States, has just gone on-line with a recycling plant designed to take nylon fixed carpet and extract from post-consumer carpet its core ingredient (caprolactam) and turn it back into virgin Nylon 6 carpet fiber. At least 98% of the material going into the process has to be Nylon 6 or the process is contaminated. And Shaw plans to take 300 million to 400 million pounds of carpet per year and run it through this plant. So the driving force for all these recycling applications isn’t to save trees—it is the cost of crude oil, which is the only alternative feed stream (for the production of nylon).”

Axsun is certainly not alone in its pursuit of this growing market for NIR spectroscopy. In 2006 Polychromix (Wilmington, MA) introduced the Phazir, another handheld NIR spectrometry platform device for industrial applications. Like Axsun’s system (the Anavo), the Phazir—which is also marketed by Ocean Optics (Dunedin, FL)—utilizes proprietary MEMS technology and is designed to function as an easily reconfigurable spectroscopic platform with “point and shoot” simplicity. The key difference between the two instruments is the light source; Axsun says its tunable diode-laser technology and MEMS detector simplifies and shrinks the overall design and eliminates many of the power and cooling requirements, while Polychromix maintains that its tungsten lightbulb source allows the Phazir to cover a broader spectral range, is more efficient in terms of light throughput, and has a longer battery life (10 hours) and source life (two to three years).

“Our core technology is a MEMS spatial light modulator that is very small, requires very little power to operate, and functions as a tunable spectral filter based on diffraction,” said Yariv Geller, director of business development and marketing at Polychromix. “And we combine this chip with a single detector so that we are able to measure the full spectrum with only one detector. This translates into lower cost and lower power consumption because you don’t have to apply temperature stabilization to a detector array.”

Other approaches

Other companies are taking a slightly different approach to this market. Ahura Scientific (Wilmington, MA) and Analytical Spectral Devices (ASD; Boulder, CO), for example, offer compact Raman spectrometers for a number of industrial applications, although the ASD technology is not handheld and the Ahura technology, which is, has so far been marketed primarily for homeland security. Even so, ASD has demonstrated that its LabSpec system offers “superior performance” in the 2300 to 2500 nm range for carpet analysis because of the device’s good signal-to-noise ratio in that region. Ahura’s initial product, FirstDefender, is used by military, law-enforcement, and forensic-chemistry personnel to quickly identify unknown solids, liquids, and mixtures in the field (versus the quantitative analysis capabilities of NIR spectrometers); the company’s latest product, the 785 nm, diode-laser-based TruScan, is designed to do the same thing in pharmaceutical and industrial manufacturing, according to Eric Schmidt, vice president of business development (see Fig. 3). In essence, he says, the company has taken what in a lab is a college-refrigerator-size analytical system and put it into an optical engine the size of a postage stamp.“The TruScan uses incoming raw material for inspection because companies want to have 100% materials verification,” Schmidt said. “Right now pharmaceutical companies are using it to ensure that everything is properly labeled. But I think we are going to see spectroscopy all over the place, from homeland security to pharmaceuticals, roadside stops for drugs, forensics for crime, recycling, meth labs—any rugged and dangerous environment where there are potentially toxic materials and you want to be able to go in quickly and collect and assess evidence.”

While Ocean Optics does not currently offer a handheld spectrometer (with the exception of marketing the Phazir system in partnership with Polychromix), the company is developing a modular approach to instrument design that it believes will make the technology compact and portable enough for more field-based applications. The JAZ platform, launched in January 2007, puts a PC display on a spectrometer that utilizes various combinations of computer modules, depending on the intended application, configured in a stacked formation. It currently features an ultraviolet/visible silicon detector (the optical sensing layer within the JAZ stack), but the company plans to migrate to an NIR bench to give customers interested in applications in this wavelength region the same functionality and adaptability.

“We have a lot of interest from our customers in taking the PC out of the equation because they want more portability and they want to collect data wherever they are—in the field, on a process line, and so on,” said Rob Morris, director of marketing for Ocean Optics. “So we decided to put the PC display on the spectrometer and make it the brain of a larger network of modules. Imagine a stack of pancakes, each performing a different function-this is what we are doing with JAZ. We’ve taken the spectrometer and display (now an OLED) and computing modules and added modules for Ethernet connection, the light source, memory, and so on. And the user doesn’t even have to know how a particular module works. It’s like your dishwasher: you don’t need to know how it works, you just need to know that if you put the dishes in and push a button, it works.”