KRISTEN FRANO and JUN ZHAO

There are many applications where being able to measure a material inside an opaque container without sampling is not only preferred, but necessary for the integrity of the analyte and the safety of the operator. Raman spectroscopy is a highly selective analytical technique that can be used for rapid and nondestructive identification of materials in pharmaceutical and safety and security industries in a portable form factor.1,2 A limitation of Raman is that measurements need to be made either directly or through a transparent container (for example, a thin, clear plastic bag).

In a controlled laboratory setting, this type of sampling may be feasible, but it is not a realistic or safe approach in a field setting. For Raman spectroscopy to be a viable technique for first-responders, customs agents, and warehouse operators, portable Raman systems need to allow for minimal contact between the sample and the operator while being able to readily identify dark and potentially impure samples. Conventional Raman probes are designed similarly to confocal Raman microscopes, where the focal point of the laser beam overlaps that of the Raman collection beam. The sample is placed at this focal point for maximum signal. This design enables easy measurement of samples through thin, clear materials such as a plastic bag.

However, this approach loses its effectiveness in a case where samples are inside visually opaque containers, such as pigment-filled plastics, which diffusely scatter the laser light so that it cannot focus on the sample inside. Consequently, the Raman signal collected will be dominated by the signal from the container with very little contribution from the sample inside. Raman measurements are also typically made over a small sampling area at the laser focus, from a few to a few hundred microns. This small laser spot limits the ability to acquire a representative measurement of a heterogeneous sample, but more importantly presents a hazard for energetic material due to the high laser power density of the measurement, causing a safety hazard for operators in a field setting.

For Raman spectroscopy to grow as a useful field identification technique in the face of real-world samples, the traditional limitations of Raman need to be overcome. This technique should be able to measure dark or impure samples in a wide variety of packaging in a manner that is safe for the user. Spatially offset Raman spectroscopy (SORS) is a technique for measuring samples through opaque containers.3 However, SORS cannot be easily converted to a confocal arrangement and thus often has difficulty with direct measurements. The laser commonly used for SORS measurements also generates fluorescence similar to that from a 785 nm Raman system.

See-through Raman technology

A recently developed see-through technology, dubbed STRaman, enables measurement of samples through opaque packaging using collinear laser excitation and Raman scattering collection at a high throughput.4,5 Using 1064 nm near-infrared laser excitation and a reflective cavity for deeper measurement with illumination spread out over a larger area, this technology overcomes the traditional limitations of field testing with Raman spectroscopy. Presented here are findings from several practical application examples of this technology for identification of unknown samples through visually opaque containers.

In order to increase light delivery and signal collection by means of multiple reflections, this technology relies on a reflective cavity, which also serves three practical purposes for measurements. First, it provides a larger laser spot size for measurements, reducing spot-to-spot variability within a heterogeneous sample that may occur with a confocal arrangement. Next, it reduces required laser power density for dark and energy-absorbing materials. And, third, it blocks ambient light that may interfere with measurements.

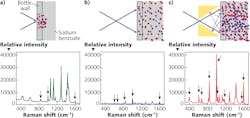

The importance of the reflective cavity is demonstrated using sodium benzoate, a strong Raman scatterer (see Fig. 1). In a traditional Raman system, the laser focus is placed at the surface of the container. With a diffusely scattering opaque container such as a white polyethylene bottle, very little of the laser will penetrate through the container to interact with the sample.

Figure 1a shows the Raman spectrum collected from sodium benzoate in a white polyethylene bottle using a standard Raman configuration. The signal is dominated by contribution from the polyethylene; the green arrows point to the contribution from the sodium benzoate, which are much weaker.

Figure 1b shows that using a defocused excitation beam that covers a larger spot size (~ 4 mm), the laser light penetrates deeper through the packaging, resulting in much weaker contribution from the packaging material. Using the high-reflectivity cavity enhances both the excitation and collected signal from the multiple internal reflections and penetrates to the sample to a greater degree.

The Raman spectrum collected with the reflective cavity in Figure 1c is dominated by signal for the sodium benzoate instead of the polyethylene packaging. This example demonstrates the importance of the reflective cavity for through-container sampling, as it can be used to minimize contact between an operator and a sample. For identification of the material, spectral libraries for packaging and sample materials and robust search algorithms can be used to isolate the sample spectrum from the packaging.

Seeing through paper layers

Several industries benefit from being able to measure samples through paper packaging. For example, many pharmaceutical companies receive raw materials in sacks of brown kraft paper, often with multiple layers. Kraft paper is made from chemical pulp and fluoresces strongly under 785 nm and shorter laser excitations.

Many illicit drugs are also packaged for distribution in folded layers of colored paper that can fluoresce with 785 nm Raman systems. Due to the potential toxicity of these street drugs, officers are at risk to open these containers in the field and are often under strict orders not to do so, leading to case overloads in forensics labs.

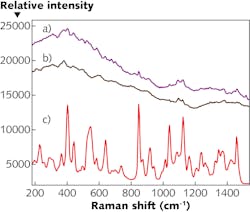

Sucrose (sugar) is a common pharmaceutical excipient that is a relatively weak Raman scatterer. To measure such a material through brown kraft paper requires a 1064 nm laser excitation source, as the kraft paper will generate overwhelming fluorescence with shorter-wavelength laser sources and makes identification impossible.

In Figure 2, spectrum (a) shows the Raman spectrum of sugar in a multilayer kraft paper bag with a thin layer of plastic lining measured using the STRaman configuration, while (b) is the spectrum of the packaging material by itself, and (c) the spectrum of pure sucrose from the library.Although the packaging material still generates significant fluorescence at the 1064 nm excitation, signatures of sucrose are clearly visible in the spectrum in Figure 2, spectrum (a), and a search algorithm identifies the substance as sucrose with a high hit quality index of 95.6.

Conclusion

While Raman spectroscopy has many advantages for unknown identification, typical Raman instrumentation has limitations in cases of samples inside of opaque packaging. STRaman spectroscopy advances the capabilities of Raman spectroscopy by allowing for measurements through opaque packaging using a large laser spot size and a reflective sampling cavity combined with spectral search algorithms and spectral libraries.

Measuring samples through opaque containers without sampling is advantageous in several applications, including pharmaceuticals and narcotics identification. A 1064 nm laser wavelength is especially beneficial in mitigating the fluorescence that can be caused by real-world samples, potentially from the analyte or from the packaging material. STRaman is able to measure difficult samples through challenging materials such as brown kraft paper, a common packaging material for pharmaceutical raw materials.

REFERENCES

1. G. Mogilevsky, L. Borland, M. Brickhouse, and A. W. Fountain, Intl. J. Spectroscopy, 2012, 808079 (2012); http://dx.doi.org/10.1155/2012/808079.

2. M. D. Hargreaves, “Handheld Raman Spectrometers and Their Applications,” Encyclopedia of Analytical Chemistry: Applications, Theory and Instrumentation, John Wiley and Sons, Chichester, England, 1–16 (2014).

3. P. Matousek et al., Appl. Spectrosc., 59, 393–400 (2005).

4. J. Zhao and X. J. Zhou, “Methods and devices for measuring Raman scattering of a sample,” US patent 10,113,969 B2 (2018).

5. J. Zhao, K. Bakeev, and J. Zhou, “Raman Spectroscopy Peers Through Packaging,” Photonics Spectra, 52, 2, 44–49 (Feb. 2018).

Kristen Frano is Applications Manager and Jun Zhao is Director of R&D and Portable Raman Product Manager, both at B&W Tek, Newark, DE; e-mails: [email protected] and [email protected]; bwtek.com.