For the first time, scientists have reportedly manipulated exciton fluxes in tiny circuits using voltage as a control, an important step in the development of optically active integrated circuits. Direct coupling of photons to exciton circuit devices may lead to the development of ultra-efficient photonic computing, say researchers at the University of California at San Diego (UCSD; La Jolla, CA) and the University of California at Santa Barbara.

Excitons are hydrogen-like bosonic particles that emit a flash of light as they decay. A type of exciton called an “indirect exciton” consists of an electron and a “hole” confined in quantum wells (QWs) separated by several nanometers. An exciton is formed when this electron and hole are created by light. A voltage gate can be used to control the flow of exciton recombination in an optical circuit, much like it can be used to control the flow of electrons in an electronic circuit.

The difficulty with using excitons for communication is that they usually decay in less than a nanosecond, making them impractical for signal transport over a significant distance. Cooling the particle extends its lifetime, but also tends to prevent recombination. To get around this difficulty, UCSD physics professor Leonid Butov and colleagues used indirect excitons, the lifetime of which is longer than regular excitons by several orders of magnitude. Because of their longer lifetime, indirect excitons have more time to travel, and so are able to operate as a potential medium for communication.

The type of semiconductor material and structure also influence the operating temperature of the excitonic device. The team built an excitonic integrated circuit (EXIC) of aluminum gallium arsenide (AlGaAs)-based coupled quantum wells (CQWs). For an Al0.33Ga0.67As/GaAs CQW structure with a separation between wells of 12 nm, the operating temperature is below about 40 K (390°F)—the maximum temperature at which electron-hole binding is enabled. Three exciton optoelectronic transistors (EXOTs), which are similar in geometry to field-effect transistors, were used to create a Y-shaped EXIC structure.

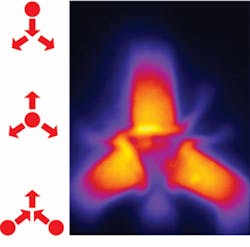

Butov’s group created several operational EXIC schemes with semitransparent electrodes used to photoexcite the excitons. One scheme allows directional switching of the exciton flux. In that scheme, an electrode photoexcited the excitons at one EXOT, the output of which traveled into split paths, left and right over two adjacent electrodes, transmitting a density of 5 × 1010 excitons per square centimeter. Another scheme used a center electrode placed between three EXOTs to photoexcite the excitons into a three-beam star geometry (see figure). Yet another scheme enabled a merging of two exciton fluxes into a single, summed flux.

The distance between the sources and drains for the EXOTs was 3 µm, which was limited by the lithographic sample processing. If the EXOT distance between sour Can we change the first one to “UV lasers image combustion flows”

And the third one to “Microcavities create novel lasers” ce and drain could be reduced to 1 µm, say the researchers, a high packing density like that of electronic integrated circuits is conceivable. One of the next steps will be to expand the possible geometries for which exciton flux can be controlled, investigating configurations such as traps, conveyers, and quantum point contacts.

REFERENCE

1. A.A. High et al., Science Express online 10.1126 (June 19, 2008).