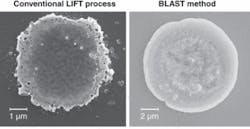

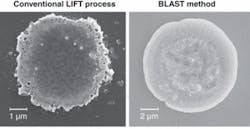

Numerous laser-based methods exist for creating patterns and textures on a substrate, including traditional lithography, direct-write methods, and exposure through self-assembled microspheres (see www.laserfocusworld.com/articles/286501 and 320263). One particular direct-write method, called laser-induced forward transfer (LIFT), brings a donor material in close proximity to a receiving substrate; a laser pulse is fired at the donor and its melted and/or ablated material is propelled toward the receiver. Although the LIFT method works well for polymers, biomaterials, and other “soft” donors, its inadequacy for patterning with “hard” materials like metal, glass, and ceramics led researchers at the University of Southampton (Southampton, England) and the National Technical University of Athens (Zografou, Greece) to create a new patterning technique called ballistic laser-assisted solid transfer (BLAST).

The secret to releasing hard donor material without damaging the receiving substrate is to use a source laser with a carefully tuned fluence value below the ablation threshold to release material in a solidified state at low speed. Using multiple subthreshold 110 fs, 250 Hz repetition-rate pulses from an 800-nm-emitting Ti:sapphire laser focused to a 12 µm spot with an annular beam shape creating higher energy at the outer edges, the researchers were able to release solid material from an 80 nm or 160 nm chromium-on-fused-silica donor and deposit it with little distortion on a silica substrate. Contact David P. Banks at [email protected].