Ultrashort-pulse lasers have already found a handful of commercial applications in which extreme precision is required. IBM uses femtosecond lasers to remove defects as small as about 10 nm on photolithographic masks for fabrication of state-of-the-art integrated electronic circuits. Femtosecond laser systems developed by IntraLase (Irvine, CA) can slice the corneal flaps needed for LASIK surgery far more precisely than conventional blades. But those are only the forerunners of an emerging generation of ultrafast laser applications, including writing three-dimensional waveguides in silica, fabricating microfluidic devices, and performing surgery inside living cells without punching holes through the cell membrane.

Ultrafast effects on materials

Illumination by intense pulses triggers nonlinear absorption processes that can change the state or bond structure of a material—causing localized expansion, contraction, or altering the refractive index inside a material—as well as ablating the surface. “We are really exploiting an interface with materials science,” says David Richardson of the University of Central Florida (Orlando, FL). Understanding these structural changes opens the way to potential applications.

For surface ablation, the big attraction of short pulses is greater precision. Pulses lasting more than about 35 ps splatter molten material around the ablated zone and heat the adjacent area enough to cause damage. Femtosecond pulses concentrate higher peak power in a smaller zone, producing nonlinear effects relatively insensitive to wavelength that blast away material with little heat left to damage the adjacent area—crucial for high-precision tasks such as mask repair.

Another attractive application is drilling small holes with high aspect ratios. At CLEO (San Jose, CA) last May, a group from Friedrich Schiller University (Jena, Germany) reported that 800 fs pulses from an amplified fiber laser could drill holes through 1 mm stainless steel in a few milliseconds if pulse rates approached 1 MHz. The high repetition rate kept residual pulse energy from dissipating out of the target area between pulses, reducing the number of pulses needed to drill through.1

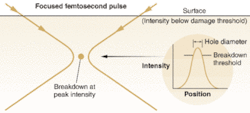

Ultrafast pulses are especially promising for fabricating three-dimensional structures in transparent solids. Focusing the beam with a high-NA lens keeps its intensity below the damage threshold at the surface, but concentrates it enough at the focal point inside the material to cause structural changes (see Fig. 1). Chris Schaffer of Cornell University (Ithaca, NY) describes three classes of effects caused by nonlinear absorption of single 100 fs pulses in glass.2The lowest level effect increases the refractive index when 40 to 150 nJ pulses are focused with an NA 0.65 lens. Details are not fully understood, but nonlinear absorption is thought by most researchers to heat the focal spot briefly above the melting point, then the glass quickly resolidifies in a denser form with a higher refractive index. Two quirks of glass contribute to the effect—its density increases with temperature, and the solid retains the higher density of the hot liquid if it cools very quickly. Firing a series of pulses while moving the focal spot can write a high-index waveguide. Schaffer says high repetition rates work best because the dynamics of melting and cooling smooth out pulse-to-pulse variations, giving a smoother waveguide with lower attenuation.

Higher power levels—pulses of about 150 to 500 nJ focused in the same way—cause birefringent changes in refractive index in alternating glass layers, creating a nanoscale grating. The electromagnetic fields in the pulses appear to deplete a thin layer of one component of the glass and enrich an adjacent layer in the same component, in the process creating planar nanocracks aligned in a direction that depends on the pulse polarization. Experiments at the National Research Council of Canada showed that the nanocracks can be erased and rewritten with light polarized in a different way, a technique potentially useful for holographic data storage.3

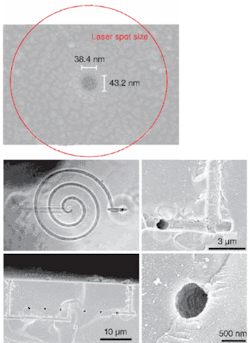

Even higher peak powers vaporize the target glass, driving the material outward from the focal point to leave a void surrounded by an overdense layer. The void can be smaller than the wavelength, (see Fig. 2, top) and a series of pulses can carve complex patterns such as a spiral beneath the surface of glass (see Fig. 2, bottom).4 One application of this effect is fabricating an internal diffractive lens or Fresnel zone plate to focus light passing through the glass. Another application is creating microfluidic channels within glass, says Alan Hunt of the University of Michigan‘s Center for Ultrafast Optical Science (Ann Arbor, MI). These can be made as narrow as 20 nm, but it‘s easier to see larger channels such as the spiral at the bottom of Fig. 2.5 Hunt uses conventional photolithography to etch planar channels on the surface, but turns to femtosecond pulses to create three-dimensional structures. He immerses the glass in liquid during fabrication to remove the laser-produced debris from the channels.

Taking surgery to the nanoscale

Femtosecond laser pulses also can be applied to delicate surgical procedures because living tissue is relatively transparent over short distances. The biggest surgical success story so far is in a niche opened by the spread of the LASIK approach to refractive surgery. The advantage of LASIK over the older photorefractive keratectomy (PRK) technique is that it preserves the outer layer of the cornea rather than ablating it. But that requires cutting a flap in the corneal epithelium with a blade and peeling it back to expose the interior for laser ablation, and problems in cutting those flaps cause most complications in LASIK patients.To improve flap cutting, Tibor Juhasz, now at the University of California at Irvine, turned to femtosecond laser pulses focused to the desired depth below the corneal surface. He founded IntraLase to commercialize the technique, which begins the cut beneath the surface, then cuts through to the surface to open the flap. The laser system is costly and patients pay a premium for it. But Shaffer says it‘s worth it. “Their complication rate is so low that they have difficulty measuring it with statistical certainty,” he says.

Femtosecond laser surgery is particularly attractive in biomedical research. “A lot of what you do in biology is to break something and see what goes wrong,” explains Schaffer. Femtosecond pulses can reach inside tissue to destroy targeted structures, such as individual nerves or subcellular structures.

Nozomi Nishimura and David Kleinfeld at the University of California at San Diego (La Jolla, CA) have shown that femtosecond pulses can injure small blood vessels to simulate ministrokes, which neurologists now recognize are a major contributor to dementia in the elderly population (see examples in Fig. 3). Large strokes are devastating because they damage large blocks of tissue, but smaller strokes affect much smaller regions in different ways, so affected cells may still get oxygen but not glucose. Femtosecond pulses give researchers the first animal model to study ministrokes, a vital step in developing therapies to minimize their impact.6

Femtosecond pulses also can destroy individual subcellular structures in more basic research. Hunt has shown that zapping an organelle linked to the programmed death of cells in the body can extend the life of the affected cell. He‘s also using femtosecond pulses to modify mechanical structures involved in cell division, to study what the structures do.

Outlook

Femtosecond pulses clearly have limitations that affect many potential applications. Like any delicate tool for changing materials, they can be slower than other techniques. Hunt says photolithography can write two-dimensional structures much faster, but ultrafast pulses are better for three-dimensional fabrication. Likewise, light pulses can‘t reach deep inside opaque materials.

But ultrafast technology clearly has big advantages in the right applications. The sheer variety of applications being investigated is impressive; this article can only describe a small fraction of the research. Potential applications are benefiting from rapid improvements in ultrafast fiber lasers that, according to Richardson, are going to have a big impact because they are smaller, less costly, more rugged, and more stable than Ti:sapphire lasers, which have long dominated the femtosecond world. And the ability to create new kinds of structures is sure to open more opportunities. Richardson is using femtosecond lasers to fabricate optical waveguides that couple light into microfluidic channels fabricated in the same integrated device—a whole new capability.

REFERENCES

- A. Ancona et al., CLEO 2008, paper CMX6.

- K. Itoh et al., MRS Bulletin 31, 620 (August 2006).

- R.S. Taylor et al., Optics Letters 32, 2888 (Oct. 1, 2007).

- A.P. Joglekar et al., Proc. National Academy of Sciences 101, 5856 (April 20, 2004).

- K. Ke et al., Analytical Chemistry 77, 5083 (Aug 15, 2005).

- N. Nishimura et al., Nature Methods 3, 99 (February 2006).