Plasma filaments generated by femtosecond-laser pulses in air are not just a spectacular effect–they are potentially useful too. Their narrow diameter (10 to 100 µm) and lengths ranging up to many meters not only serve as an extended channel for the femtosecond laser pulses themselves, but can also guide microwaves or powerful electric currents. However, the plasma normally lasts only a few nanoseconds, making it harder to create long-distance filaments.

But now, scientists at the Centre National de la Recherche Scientifique (CNRS; Palaiseau and Villeurbanne, France) have figured out a way to rejuvenate a seemingly vanished laser filament even milliseconds after it disappears by using focused nanosecond laser pulses. The revived filament lasts for longer than a microsecond and can even be further boosted to have an electron density exceeding that of the original filament.

Revival by nanosecond pulses

For a typical laser-created plasma filament starting out with a free-electron density of 1016 to 1017 cm-3, most of the free electrons are captured by their parent ions within a few nanoseconds; when the free-electron density drops below 1014 cm-3, and the filament appears to be gone, the few remaining free electrons are captured by neutral oxygen molecules in a much slower process with an exponential-decay time constant of about 150 ns.

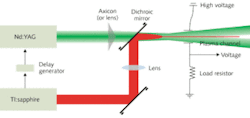

The CNRS researchers exploit this subsequent slower process by sending a second, nanosecond-duration laser pulse, focused by an axicon into a Bessel beam, along the path of the former filament to detach the weakly bound electrons from the neutral oxygen molecules; the pulse then multiplies the free electrons through an avalanche process (see figure). The interesting thing is that the second laser pulse is at an intensity well below the level that can ionize air. Then, a third laser pulse can be used to further multiply and accelerate the free electrons.

The initial pulse that created the laser filament was either a 15 mJ, 50 fs pulse with a center wavelength of 800 nm generated by a Ti:sapphire chirped-pulse-amplifier chain, or a 150 fs, 250 mJ pulse from the Teramobile laser. The second pulse, from a frequency-doubled Nd:YAG laser, had a pulse duration of 10 ns and an energy ranging between 100 and 250 ns. The third pulse was at the fundamental wavelength (1064 nm) from the same Nd:YAG laser, and was also 10 ns in duration.

The presence of a plasma was detected by two parallel metal plates with a voltage across them, and with a photomultiplier tube with a narrowband centered at 338 nm–the emission line for ionized nitrogen molecules. The second pulse revived the plasma over a 50 cm length (a longer distance could be revived if higher-energy pulses and a larger initial beam diameter were used, say the researchers).

For experimental purposes, the third beam crossed the other two beams at a 10° angle. The third pulse followed the second by 10 ns; the third produced the bright spark that indicates fully developed optical breakdown; the restored plasma lasted at least 1 µs, and produced an optical signal exceeding that of the original filament for more than 200 ns.

REFERENCE

- B. Zhou et al., Optics Express 17(14) p. 11450 (July 6, 2009).