In communications, as in many things, low cost means plastic; for example, the price of short-haul fiber-optic communications systems is lower because of the increasingly widespread use of plastic optical fibers (POFs). Researchers at Queens College of the City University of New York (CUNY; Flushing, NY) are making their own contribution to this beneficial shift in materials by developing quantum-dot (QD) polymer hybrid vertical-microcavity lasers that are not only flexible, but also are made with low-toxicity QDs and are thus environmentally benign.1 The lasers emit at 657 nm–right at the attenuation minimum of POF.

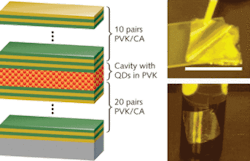

In addition, the spin-coating fabrication process for the laser is relatively simple and adaptable to large-scale manufacture. The distributed-Bragg-reflector (DBR) cavity mirrors consist of alternating quarter-wave layers of poly-N(vinylcarbazole), or PVK, with a refractive index of 1.638 at (600 nm), and cellulose acetate (CA) with an index of 1.475. One interesting point about the two DBR materials: the researchers were able to choose two solvents, each of which dissolved a different polymer, leaving the other untouched, easing the fabrication process.

The laser is formed on a glass substrate. The microcavity itself consists of a half-wave layer of PVK with about a 2% fill factor of indium gallium phosphide (InGaP) QDs. Unlike other QDs based on cadmium or lead, the InGaP QDs do not result in biohazardous waste. After fabrication, the laser, which is in sheet form, can be simply peeled off the substrate (see figure).

Prototype performance

Using a fiber-coupled tungsten-halogen lamp and the laser sheet laid out flat, the researchers found the quality factor of the microcavity to be about 70; with light from a 488 nm argon laser, they measured a cavity-linewidth-limited emission line. Next, they wrapped the laser sheet around glass cylinders with radii of 0.5 and 1.0 cm, comparing the results to those from the flat orientation. For light collected at an angle of 20° from the normal, the light blue-shifted by a few nanometers and decreased in intensity as the bending radius was decreased. For light emitted at normal, there was no blue-shift or intensity change due to bending.

When optically pumped with 5 nm pulses at the 532 nm second harmonic of a Nd:YAG laser, the device lased at a threshold of 27 mW and reached an emission of about 2 mW at a pump power of 52 mW; the emission linewidth (full width at half maximum) dropped from 8 nm below the laser threshold to under 2 nm at threshold.

Vinod Menon, one of the researchers, says that the group is working on multicolor flexible microcavity lasers using QDs of varying composition. In addition, the researchers believe that with a charge-injection scheme, an electrically pumped version of the laser is feasible.

REFERENCE

- V.M. Menon et al., Optics Express 16, p. 19536 (Nov. 24, 2008).