The vast majority of white-light LEDs in use today consist of the combination of a blue-emitting gallium nitride (GaN)-based diode source and a yellow YAG:cerium phosphor. Although this combination tends to produce poor-quality white light, it is cheap and reliable. Researchers at the Huazhong University of Science and Technology (Wuhan, China) are aiming to create another practical white-light-LED combo: near-UV LEDs and doped borosilicate luminescent glass. When illuminated by UV light at 346 nm, the glass, which is co-doped with cerium, terbium, and manganese, emits red, green, and blue—ideally producing a pure-white light. Although prototypes don’t achieve this yet, the researchers are working to increase their color-rendering index (CRI; a measure of white-light quality).

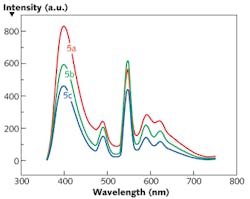

The glass is made from its oxide, carbonate, and dopant raw materials by melting and keeping them all at 1580°C in a reduction atmosphere (to keep the doped ions in the appropriate valence state). The melts are then annealed for two hours in molds at 550°C. The samples (5a, 5b, and 5c) each had slightly different co-dopant concentration, and thus different emission spectra. Sample 5c had a CRI of 82.9, which is slightly better than that of a standard white LED (the other two samples didn’t fare so well). In addition to improving the CRI, the researchers will try to decrease the color-correlated temperature (make the light less blue).

Contact Luyun Yang at [email protected].