Using laser-induced breakdown spectroscopy (LIBS), a team from Hefei University of Technology (Hefei, China) has discovered the process of identifying and categorizing waste materials for recycling—at both the consumer and industrial levels—could be more efficient, rapid, and accurate (see video).

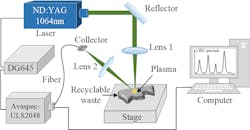

A technique used for elemental compositional detection, the LIBS system comprises a high-energy pulsed laser, a spectrometer, and a digital delay generator (see Fig. 1). The high-energy laser passes through lenses and irradiates the surface of a sample—in the Hefei team’s research, the sample is recyclable waste.

This produces dielectric breakdown of the formation of plasma, explains researcher Lei Yang, a professor at Hefei’s School of Instrument Science and Opto-electronics Engineering. The plasma emission light is collected by the spectrometer component for spectral analysis, while the digital delay generator controls the working time between the laser and spectrometer to avoid collecting continuous spectra and instead acquire characteristic spectra corresponding to the elements of the sample, with a high signal-to-noise ratio.

“We have utilized LIBS technology to achieve fast and accurate identification and classification of recyclable waste from two levels,” Yang says. “One is from the consumer level, where recyclable waste is classified into six categories. The other is from the recycling factory level, where metals and plastics are sub-classified separately.”

In their work, the team analyzed the six waste materials—paper, plastics, glass, metals, textiles, and wood. By classifying these into subcategories, they were able to make more precise identifications of complex materials (see Fig. 2). Supplemented by machine learning models, the classification process reached 100% accuracy.

Why LIBS?

Resource reuse is generally classified based on the sample’s elemental composition. Therefore, classification methods—namely LIBS—that are based on the sample’s elemental composition will have high accuracy (see Fig. 3).

“If automatic identification and classification of waste are achieved based on the waste composition, it will bring more convenience to residents and recycling factories,” Yang says.

LIBS technology offers several advantages over conventional methods for classifying recyclable waste. It doesn’t require pretreatment of the sample; it’s also fast, simple to operate, and can simultaneously detect multiple elements, which makes possible online and automated organization and identification.

“LIBS identifies and classifies waste according to its elemental composition with high classification accuracy,” Yang says.

Other methods rely on just physical characteristics and images. This isn’t very accurate, Yang notes, due to several factors—environment, lighting, and waste geometry, for example—and they cannot achieve refined classification. Commonly used approaches such as infrared spectroscopy as well as hyperspectral and fluorescence spectroscopy don’t work well, as they require pre-treatment of waste and they’re more complicated to operate; they also cannot achieve automatic detection.

“LIBS has the advantage of in situ detection and rapid analysis, independent of environment and sample,” Yang says. “This overcomes the disadvantages of other methods of classification.”

Sustainability of the future and beyond

The sustainable development and reuse of resources are an important part of a green, low-carbon, and circular ecology system, of which waste classification is an indispensable part. The identification and classification of recyclable waste is a prerequisite for turning it into useful resources while also achieving waste resource utilization, recycling, and resource conservation.

“Starting from the generation of waste, LIBS’ accurate identification and classification of garbage can be automatically achieved at different levels, leading to the reuse of useful resources,” Yang says. “It can provide new ideas and methods for waste management, domestic and industrial waste classification, and resource recovery, and is of great value in promoting a green ecology.”

The next steps include increasing the types of categories of other samples such as hazardous waste and kitchen waste. The number of waste samples tested in each category will increase significantly, as well, according to Yang. The team will also delve deeper into subclassified categories and investigate the amount of waste based on industrial processing and reuse needs.

“Our ultimate goal is to achieve automatic, fast, and accurate waste identification and classification,” Yang says. “To achieve a broader range, we could also combine it with other technologies such as machine vision.”

Already applied in a variety of fields—environmental monitoring, metal material analysis, geological prospecting, medical diagnosis, cultural relic protection, and industrial realms, among them—LIBS may also someday be used to analyze and categorize gases, liquids, and solids. Ocean exploration is another application for which LIBS works well, Yang notes, as is space exploration. For example, NASA’s Curiosity Mars Rover ChemCam instrument is equipped with a LIBS system, which is used to detect mineral matter composition on the surface of Mars.