A new demonstration of random lasing in a boundary-free system has shown new avenues to create random lasers in disordered systems. For most lasers, scattering is an undesired effect leading to losses. Random lasers, on the other hand, depend on multiple scattering events to achieve their effects. Instead of a cavity that contains photons, random lasers use the scattering process as a mode of containment, providing enough time for a pump source to create inversion.

Now, Antonio De Luca and colleagues at the University of Calabria (Rende, Italy) and Case Western Reserve University (Cleveland, Ohio) have demonstrated that the random lasing process doesn’t depend on the boundaries of the system containing the lasing medium. They have used freestanding films of nematic liquid crystals, whose molecules tend to be aligned along a preferred direction but distributed anisotropically.

While much work has been done on both highly ordered and highly disordered systems to achieve random lasing, De Luca says that the intermediate range of partial disorder had remained unexplored. So in 2006 the team investigated nematic liquid crystals doped with a fluorescent pyrromethene dye as their partially disordered system. The sample was held between two glass/indium tin oxide plates and pumped with nanosecond pulses at 532 nm. Beyond a threshold pump pulse energy, the isotropic fluorescence signal collapsed, leading to lasing with a preferred direction dictated by the alignment of the liquid crystal molecules. The lasing consisted of several overlapped spots that fluctuated in time over picosecond and nanosecond timescales, a result of the fluctuations of the local dielectric constant within the liquid crystals.1

But questions remained about the mechanism of the lasing. “Usually the mixture of liquid crystal and dye is contained between two aligning glasses, that transfer the partial order to the bulk,” De Luca says. “The possibility that these boundaries could be responsible for the final lasing results induced us to consider the idea of a freely suspended film sample.”

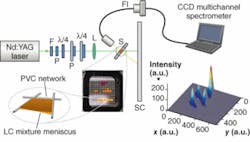

To test the idea, the team used a PVC net (see figure) and simply dropped a solution of the liquid crystal/dye mixture onto it with a pipette. Not only did the system lase just the same, the pump energy threshold for lasing was reduced. They attribute the effect to the lack of boundaries that promote both absorbance and guided modes.2

REFERENCES

1. Strangi et. al., Opt. Express 14, 7737 (2006).

2. Ferjani et. al., Opt. Lett., to be published.