Although critical-angle refractometry techniques are well-established for measuring the refractive index of homogeneous transparent materials with an uncertainty on the order of 10-6, these techniques only measure the index at a smooth, planar surface of the material–a problem for soft biological materials, considering that any surface treatments can easily modify refractive index. Building on the application of rotationally and angularly resolved low-coherence interferometry (LCI) and standard optical coherence tomography (OCT) techniques for imaging and birefringence measurements, researchers in the Biophotonics Group at the National Physical Laboratory (NPL; Teddington, England) are using Michelson LCI and a commercial OCT system to determine the internal phase index of a plane-parallel material by taking multiple thickness measurements at different angles of incidence.1

By using Snell’s law and optical-thickness measurements from at least two angles of incidence, the phase refractive index of the material can be measured for a transparent or semitransparent sample. Because such measurements at only two angles of incidence have a high uncertainty, measurements can be taken at three or more different angles of incidence and a least-squares fit applied to the set of unsolved equations to determine a more certain value for refractive index. The researchers also modified their calculations to take into account systematic angular uncertainties in the plane of rotation, the orthogonal plane, and in the measurement depth of the sample.

Testing the technique

To test the robustness of the measurement technique, a pure silica test plate and a resin-based composite slab with bulk scattering properties similar to those of human skin (and each with a thickness of approximately 1 mm) were measured using the LCI multiple-angle-of-incidence technique. Measurements were made using a commercial OCT microscope from Michelson Diagnostics (South London, England) with a 110 nm bandwidth source centered at 1310 nm and a computer-controlled motorized tilt stage to adjust angle of incidence.

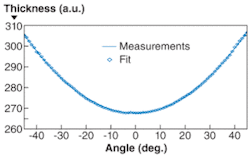

The OCT images were used to measure sample thickness at 1° intervals from -45° to +45° from normal incidence (see figure). Using OCT images is especially advantageous, considering that measurements at each angle could be averaged; also, the top and bottom surfaces of the sample were identified on each measurement using a Gaussian-peak-fitting algorithm and a linear regression. From those surface locations, the thickness of the sample was determined at each angle. Angular tilt was not measured using OCT; instead, angular data was obtained from the tilt platform encoder. The refractive-index equations, including correction for systematic uncertainties, were fitted to the measured thicknesses using a Gauss-Newton algorithm.

The silica refractive index from the fitting routine was calculated as 1.447 ± 0.002, which compared well with the 1.4466 ± 0.0002 result from a commercial Abbe refractometer (from Bellingham and Stanley, London, England) measurement at 1300 nm. However, the resin-based composite could not be measured on the Abbe refractometer due to scattering. The measured refractive-index value using the Michelson LCI technique was 1.550 ± 0.002. Additional attributes of the measurement technique include the ability to make measurements without requiring a highly polished surface, and the ability to measure samples with a refractive index higher than 2.

“This work represents an important step toward our ultimate goal of measuring three-dimensional refractive-index distributions within human tissue and relating this to pathology,” says Pete Tomlins, senior scientist in biophotonics at NPL. “Refractive index is a poorly understood property of biological tissues; however, it is fundamentally important for understanding how light interacts and propagates through it. The ability to measure spatial refractive indices will enable us to discover its statistical variation over time and between people and tissue types. Abnormal variations in refractive index are expected to arise in diseased tissue due to changes in its constituent chemical makeup. Hence, this research marks an important step forward for optical diagnostic and therapeutic technologies.”

REFERENCE

- P.H. Tomlins et al., Optics Lett. 33(19) 2272 (Oct. 1, 2008).