A spectral-broadening technique developed by Tamas Nagy and Peter Simon at the Laser-Laboratorium Göttingen has allowed them to produce sub-25-fs deep-UV pulses with an energy of 200 µJ per pulse—an order of magnitude higher than any previously reported results.1 Such pulses are useful for studying nonlinear interactions of deep-UV light with matter on an ultrashort timescale (photoionization, photodissociation, and so on) as well as generating energetic extreme-UV pulses and ultrashort electron bursts. The technique is based on a hollow glass fiber filled with noble gas, which produces spectral broadening via self-phase modulation, a nonlinear optical effect.

The fiber, which must be very straight to minimize waveguide losses, is held by its two ends and stretched to keep it in line. The 2-m-long fiber has an inner diameter of 320 µm. The light source for the setup is a hybrid system containing a Ti:sapphire and a krypton fluoride (KrF) excimer laser, whose pulses are compressed by a grating to a transform-limited 110 fs duration.

High-f-number optics

The laser pulses, which have a diameter of 12 mm and an energy of 2.9 mJ, are focused into the fiber by a dual-mirror off-axis optical system with an extremely high f-number of 550 (equivalent to a numerical aperture of 0.00084). This value is so high because the gas core of the fiber does not guide light by total internal reflection, and thus the beam through the fiber must be made at least as narrow as the core throughout the fiber length. (Even so, the fiber acts as a waveguide, affecting the beam’s modes.)

The gas in the fiber can be either helium or neon. Gas pressure at the output end is kept at about 2 bar, and at a vacuum at the input end; this results in a gas flow and a longitudinal pressure gradient. The interaction of the laser pulse with the gas spectrally broadens the pulse, which is then compressed downstream by another grating.

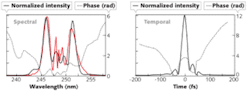

The resulting pulses are energetic enough that they can be measured by a single-shot frequency-resolved optical gating (FROG) measurement (see figure). Using neon as the gas, a pulse duration of 24.0 fs at a FROG error of 1.1% was obtained for a grid size of 256. The researchers believe that if chirped mirrors were used instead of the lossy grating compressor, the 200 µJ energy of the compressed pulse could be increased by a factor of 1.5 to 1.7, and could result in a pulse duration closer to the transform limit of about 18 fs, says Tamas Nagy.

Adding a second stage

If a second spectral-broadening stage were to be cascaded after the current experimental setup, and then the pulses compressed, a final pulse duration of less than 5 fs is expected, according to Nagy.

“It is important to note that the quality of the final pulse depends sensitively on the method of final chirp compensation,” Nagy explains. “Because of the broad bandwidth, the higher-order chirp (which cannot be compensated by a grating compressor) plays a crucial role; therefore, the use of chirped mirrors after the second stage is essential.” Ideally, he says, a pulse duration of about 4 fs with an energy of several tens of microjoules should be obtained.

“Please note,” he adds, “that it is not the pulse duration alone, but the expected high pulse energy combined with the few-cycle duration that makes our approach unique.”

REFERENCE

- T. Nagy and P. Simon, Optics Lett. 34(15) p. 2300 (Aug. 1, 2009).