Ultrafast lasers have long been confined to a sleepy corner of the laser market, reserved for the most exotic R&D applications. Now, not only does it seem that every laser supplier is offering an ultrafast laser, but a great many of them are offering ultrafast fiber lasers, and now two even offer ultrafast thin-disk lasers. What has happened to this sleepy corner?

The new technology begs for an exact definition of ultrafast laser. Our definition of ultrafast lasers overlaps with modelocked lasers, excluding all diode lasers unless they are mode-locked. Everyone will agree that “ultrafast” includes femtosecond lasers. Some stop there, either because they are purists or because they don‘t want their picosecond lasers to be considered as exotic and expensive as femtosecond lasers. In fact, picosecond lasers were once considered the limit of ultrafast, before pulse compression came along, and are now seen as superior to femtosecond lasers for microfabrication of many materials. In our definition, we include both picosecond and femtosecond lasers.

Ultrafast lasers have been confined to the R&D corner of the market for a simple reason. If lasers are often the tool of last resort, then ultrafast lasers are the last resort among lasers. In other words, the end-user will use a drill, a surgical knife, or a lamp if it can do the job more easily and cheaply. And when a laser is used as a tool, a CW or Q-switched laser will usually do the job more easily and cheaply than an ultrafast laser.

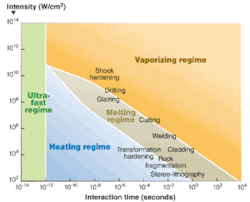

However, these other lasers are like jagged saws compared to the fine scalpel of the ultrafast laser. The ultrafast laser is perfect for making very clean cuts in materials with little or no thermal damage. These materials could be microfluidic devices, patterned semiconductors, human tissue, explosives, and so on. The reason is that the ultrafast pulse imparts energy very quickly. It can boil away material or initiate multiphoton processes in a controlled fashion, before the heat that is created diffuses away. This allows for an athermal process, or at least a process with minimal heat damage. But this fine-toothed saw is simply too fine for most laser-processing applications.

The ultrafast pulses are also very efficient for producing nonlinear effects, like wavelength conversion and multiphoton absorption, for use in wafer inspection and biomedical imaging (see www.laserfocusworld.com/articles/332968). They also allow the observation of time-dependent phenomena for spectroscopy and particle physics, and can provide a very stable, high-frequency pulse train for metrology.

Ultrafast fiber, defined

The first ultrafast lasers were dye lasers and solid-state lasers, decades ago. Titanium-doped sapphire and fiber lasers were commercialized in the early 1990s, within a few years of each other. Ti:sapphire has dominated in ultrafast for many years, and will continue to dominate for the very highest peak power and the shortest pulse widths. But fiber lasers have made progress in these areas (see www.laserfocusworld.com/articles/328528), and are well suited for many more mainstream ultrafast applications. They feature the usual advantages of fiber lasers: compact and robust design, low maintenance, and consistently high beam quality.

In the ultrafast realm, however, it is hard to precisely define a fiber laser. For example, last May Coherent (Santa Clara, CA) announced a new ultrafast laser at CLEO 2008 (San Jose, CA), the Talisker, which features a fiber-based oscillator that feeds a solid-state amplifier. Last year, Newport (Irvine, CA) introduced a new ultrafast laser, the Pantera, which features a solid-state oscillator that feeds a fiber amplifier. Meanwhile, IMRA (Ann Arbor, MI) and other suppliers feature lasers with all-fiber designs. Some in the industry consider both of these types fiber lasers.

Complicating the issue further is the way that ultrafast lasers are sold. Some savvy researchers can buy laser modules, like oscillators and pump lasers and amplifiers or optical parametric amplifiers (OPAs), and assemble a benchtop system, while others buy a customized all-in-one solution. Some suppliers sell their modules to other suppliers, while some prefer to make their own.

Meanwhile, Time-Bandwidth Products (Zurich, Switzerland) and Trumpf (Farmington, CT) each introduced ultrafast thin-disk laser products recently. These products are impressive, with average powers up to 50 W.

Laser technologies are mostly friendly rivals, like the U.S. presidential contenders for 2008. The difference is that (by our count) 37 companies offer an ultrafast laser product. Each of these manufacturers compete against each other for a larger slice of the pie, and against nonlaser solutions, whether a mechanical drill, surgical saw, or UV lamp. Unlike the presidential contenders, all laser suppliers can achieve growth if the size of the pie increases fast enough. In fact what usually happens is that each finds a niche where it performs best, and the market fragments once again.

A classic example of how the laser market—and especially ultrafast lasers—works is the partnership between IMRA and Carl Zeiss Meditec (Jena, Germany) to develop an ophthalmology tool that uses an ultrafast laser for both the laser keratome (replacing a mechanical blade) and the refraction procedure (replacing an excimer laser). Meditec‘s effort has taken years to pass through product development and regulatory approvals, but eventually IMRA could to do very well from it. Success comes through patiently working with the right customers. It‘s impossible to make a quick buck (or euro or yen) in ultrafast lasers.

The bottom line

The overall market has a moderate size: about $260 million in 2007, and the growth rate is healthy, but not explosive. Fiber lasers are often viewed as the path to lower-priced ultrafast lasers. With high-pulse-energy femtosecond lasers priced at $300,000 and the grandest projects costing tens of millions of dollars, lower-power ultrafast-fiber and solid-state lasers can sell for less than $50,000 in some cases. The conventional wisdom is that if the price of ultrafast lasers comes down enough, the market will expand.

The problem is that ultrafast lasers are as far as you can get from a standard product. They are the laser of last resort for a reason: every specification comes with a cost. This means that orders count in the single or at most tens of units, but margins are high. Lower prices would drive more sales, true, but even if ultrafast lasers were free, they would not be used in most industrial laser applications.

Nonetheless, ultrafast lasers bring margins; they can do plenty of things really well and the list gets longer every year. Success in the laser industry is really about patiently serving niche customers who are first to bring new applications to market, and there are many opportunities in the coming years for laser suppliers who can do just that.

Editor‘s Note: An excerpt of this story appeared in the June 15, 2008, issue of Optoelectronics Report.