Unlike gas and solid-state lasers that emit in a characteristically narrow beam, edge-emitting semiconductor lasers have a wide beam divergence, requiring bulky optics and meticulous alignment to collimate the light. Applied-physics professor Federico Capasso and researchers at Harvard University (Cambridge, MA) and Hamamatsu Photonics (Hamamatsu City, Japan) have demonstrated for the first time highly directional semiconductor lasers with an intrinsic beam divergence 25 times smaller than that of conventional laser diodes.1 The innovation means unprecedented coupling efficiency and steering flexibility in a wide range of applications in photonics and communications. Harvard University filed a patent on the invention, which has been dubbed “a contact lens for lasers.”

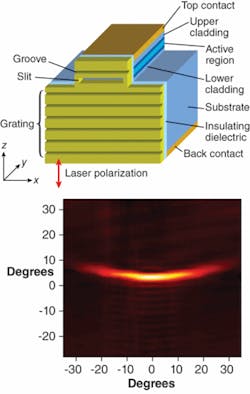

Capasso’s graduate student, Nanfang Yu, along with colleagues at Harvard’s School of Engineering and Applied Sciences (SEAS), and a Hamamatsu Photonics team headed by Hirofumi Kan, general manager of the Laser Group, used a so-called plasmonic collimator to narrow the beam divergence of quantum-cascade-laser (QCL) emission. A plasmonic collimator uses a metallic thin-film grating effectively like an antenna array. To achieve this, the group carved a one-dimensional grating pattern consisting of 24 subwavelength grating grooves directly onto the facet of a mid-infrared (9.9 µm) QCL. Thin layers of aluminum and gold were then deposited on top of the grooves. Near the top of the facet and over the emitting aperture, the group then sculpted a slit with a vertical width smaller than that of the free-space wavelength of the outgoing laser light. The grating causes an interference pattern that generates surface-plasmon (SP) modes while the slit efficiently couples the laser output into SP waves.

Experiments showed the QCL beam divergence was narrowed in the vertical direction to 2.4° compared to an unpatterned QCL divergence of approximately 63°, without significant reduction in output power (see figure). The laser maintained a maximum output power of approximately 100 mW at room temperature, with a slope efficiency of roughly 90% of the original unpatterned laser.

The far-field view of the diverged beam shows a narrow line of emission, which can be useful in surface-emitting applications. The slight curvature of the line is an edge effect, says the team; models have shown that two-dimensional concentric half-ring grooves should generate radial SPs that would diverge in both the vertical and lateral directions (2.7° and 3.2°, respectively) at λ = 8.06 µm.

The slit-grating structure can potentially collimate beams of a variety of lasers, including edge-emitting and surface-emitting semiconductor lasers at wavelengths from visible to telecom and beyond. Semiconductor lasers with narrowed beams could be used for long-range chemical sensing in the atmosphere, including homeland security and environmental monitoring, without requiring bulky collimating optics. “It is an important first step toward engineering laser beams with unprecedented flexibility,” says Capasso. “In the future, we envision being able to achieve total control of the spatial emission pattern of semiconductor lasers such as a fully collimated beam, small divergence beams in multiple directions, and beams that can be steered over a wide angle.”

REFERENCE

1. N. Yu et al., Nature Photonics advance online publication, July 27, 2008.