Multicomponent phosphate glasses are excellent host materials for amplifiers and lasers, offering high solubility for rare-earth ions, excellent optical properties, and resistance against damage by high optical powers.

AXEL SCHÜLZGEN AND NASSER PEYGHAMBARIAN

Forty-five years ago, only three years after demonstration of the first working laser, lasing action was observed in a doped optical fiber.1, 2 However, the work on fiber lasers—or more broadly speaking, active fiber devices—only took off after the development of techniques for reliable fabrication of doped single-mode fiber and fiber-optic components during the 1980s. Clearly, the driving force for technological advances in fiber optics was, and for the most part still is, optical communications.

Due to the dramatic impact and commercial success of erbium-doped fiber amplifiers (EDFAs) in the 1990s, both the scientific community and the communications industry have invested heavily in the development of doped fiber.3, 4 As a result, fiber design and fabrication techniques have advanced at an enormous rate. Profiting from these developments, both continuous-wave and pulsed fiber lasers have evolved into commercial products that are ready to compete in a significant number of application areas including industrial materials processing, optical communications, and sensing, as well as medical and military markets.

Advanced glasses and fiber designs

To take full advantage of the potential of fiber lasers, advanced glass materials and fiber structures are a necessity. Today, state-of-the-art fibers for fiber lasers can be considered advanced structural materials incorporating special glass types and containing structures smaller than one micron (materials research meets nanophotonics). There are many types of active fibers that can be selected to build an applications-specific fiber laser. In the selection process, the availability of compatible fiber-laser components such as fiber Bragg gratings (FBGs) must be taken into account to retain the main fiber-laser advantage of a robust, all-fiber architecture.

In the early years, active fibers for fiber lasers were basically a slight variation of data-transmission fibers and consisted of two low-loss glass materials and a step-index design for core and cladding; the primary difference being the doping of the fiber core with rare-earth ions to achieve the necessary optical gain. Because of its excellent optical properties and a manifold of readily available fiber components, silica has been the base glass of choice for many years. Unfortunately, pure silica can incorporate only very small amounts of rare-earth ions before microscopic clustering appears and the emission properties deteriorate.

Among the most promising alternative materials for fiber lasers are multicomponent phosphate glasses. Known to be excellent host materials for bulk glass amplifiers and lasers, phosphate glasses offer high solubility for rare-earth ions, resist damage by high optical powers, and can be drawn with excellent optical and mechanical properties. The main reason for limited application of phosphate glass to fiber-laser devices was, until very recently, their lack of photosensitivity, which prohibited direct writing of gratings into phosphate-glass fibers.5

A major step toward fibers tailor-made for fiber lasers was the introduction of double-cladding fiber, designed to enable optical pumping with high-power multimode diode lasers.6 Efficient pump-light absorption and subsequent stimulated emission by rare-earth ions within the doped fiber core leads to conversion of high-power but low-brightness input light into a high-brightness, diffraction-limited fiber-laser output.

Doped cores with a very large area are used to boost output powers and energy storage because detrimental nonlinear optical effects and optical damage are reduced. A novel concept to increase the core area while maintaining single-transverse-mode operation is the application of microstructured or photonic-crystal fibers (PCFs).7 These PCFs consist of a regular array of air holes and a defect in the center that defines the core. The most-studied PCFs with large core areas are fibers in which one central hole is replaced by a solid core; however, large core areas can also be realized with designs in which more than one central air hole is removed (for example, fibers with seven missing central air holes; see Fig 1).8 While most PCFs are made of silica, some microstructured fibers have recently been fabricated from soft glass materials.9 When the core area of these fibers is doped with rare-earth ions, such large-core, highly doped PCFs can be used to build very compact fiber lasers.

Watt-level fiber laser with FBG

Single-frequency fiber lasers find applications in optical sensors and communication systems. The fabrication of compact, single-frequency fiber lasers was enabled by the development of FBGs. Exclusive oscillation of just one laser mode in a linear cavity can be achieved by combining narrowband FBGs with short, rare-earth-doped, single-mode active fibers. However, the required short cavity length and the corresponding small pump absorption typically limits the power of single-frequency erbium-doped silica fiber lasers to power levels from hundreds of microwatts to a few milliwatts.10 Recently, phosphate glass fiber with high rare-earth-ion concentration in the core was utilized to significantly increase the absorption of single-mode pump light; 200 mW of single-frequency emission was demonstrated.11 In such a core-pumping scheme the oscillator power is still limited to a few hundreds of milliwatts by the available single-mode pump power.

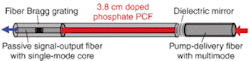

By combining highly erbium/ytterbium (Er/Yb)-codoped phosphate glass fiber with the PCF concept for large-area single-mode cores, our group has demonstrated a single-frequency fiber laser that is pumped by high-power multimode diode lasers (see Fig. 2).12 The fiber oscillator contains only 3.8 cm of active phosphate glass PCF with the geometry of seven missing air holes previously described. A linear laser cavity is formed between a broadband dielectric mirror on the pump side that transmits the 980 nm pump light and is a high reflector for the signal in the 1.55 μm Er emission band and a narrowband FBG at the output side that selects the single-emission wavelength. In this cavity, the pump light is converted into a single-mode, single-frequency light beam with a fiber-laser output power of 2.3W.

Cladding-pumped phosphate glass DFB fiber laser

The distributed-feedback (DFB) laser is a well-known alternative to single-frequency laser cavities that use FBGs. A DFB laser cavity is formed by a phase-shifting defect inside a grating structure. The rather simple fabrication of these devices involves imprinting a grating structure into an appropriate doped fiber. However, building a DFB laser requires that the doped fiber is photosensitive—a feature lacking in most glasses with high solubility to rare-earth ions.

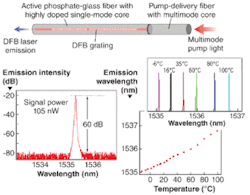

Very recently we demonstrated a DFB fiber laser based on highly doped and also ultraviolet (UV)-photosensitive phosphate glass (see Fig. 3).13 To our knowledge, this is the first DFB fiber laser that is pumped by multimode diode lasers launched into the fiber cladding, a feat made possible because the core of the single-mode gain fiber is fabricated from phosphate glass that is highly doped with 1.1 × 1026 Er3+ ions/m3 and 8.6 × 1026 Yb3+ ions/m3. The DFB grating structure is written directly into the doped fiber by exposure to 193 nm UV light through a phase mask. The grating structure consists of a 2-cm-long section close to the pump side and a 1.5-cm-long section at the single-mode DFB emission side that are separated by a 50-μm-wide gap that creates the defect state inside the grating‘s reflection band. The asymmetric design results in unidirectional DFB laser emission to the left.

With the multimode pump-delivery fiber spliced to the active fiber, this laser device contains no moving or adjustable parts and shows very stable single-frequency emission with a side-mode suppression ratio of over 60 dB and a maximum output power of 160 mW. In addition, the lasing wavelength can be rather widely tuned by adjusting the grating temperature. Another important feature of this novel DFB cladding-pump scheme is the easy implementation of a fiber-laser cascading scheme14 A single high-power multimode pump light source can be utilized to pump a string of DFB resonators imprinted into the same active fiber. Such a cascaded laser device can be designed to emit at various desired wavelengths.

In the future, new host glass materials and dopants will enable fiber lasers to emit at an ever larger variety of wavelengths. In particular, fiber lasers for the infrared where conventional glasses such as silica start to absorb light will require the development of new host glasses, associated fiber drawing techniques, and compatible laser components. Doped fibers with built-in microstructures will become key components for a good portion of fiber lasers and will help to steadily improve performance characteristics.

ACKNOWLEDGMENT

The authors thank Jacques Albert‘s group at Carleton University in Ottawa, ON, Canada for the fabrication of fiber grating structures. We also acknowledge support by the National Science Foundation through grant No. 0725479 and the state of Arizona Technology Research & Initiative Funding (TRIF) program.

REFERENCES

- E. Snitzer, Proc. 3rd Intl. Conf. Solid Lasers, Paris, France 999 (1963).

- C.J. Koester and E. Snitzer, Appl. Optics 3(10) 1182 (1964).

- R.J. Mears et al., Elect. Lett. 23, 1026 (1987).

- E. Desurvire, J. Simpson, and P.C. Becker, Optics Lett. 12(11) 888 (1987).

- J. Albert et al., Appl. Phys. Lett. 89, 101127 (2006).

- H. Po et al., Optical Fiber Communication Conf. 1989, paper PD7, Houston, TX (1989).

- P. St. J. Russell, Science 299, 358 (2003).

- 8. J. Limpert et al., Optics Exp. 12, 1313 (2004).

- T.M. Monro and H. Ebendorff-Heidepriem, Ann. Rev. Materials Res. 36, 467 (2006).

- J.M. Jauncy et al., Elect. Lett. 24, 24 (1988).

- C. Spiegelberg et al., J. Lightwave Tech. 22, 57 (2004).

- A. SchÜlzgen et al., Optics Exp. 14, 7087 (2006).

- A. SchÜlzgen et al., Optics Lett. 33, 614 (2008).

- L.Li et al., Appl. Phys. Lett. 92, 051111 (2008).

AXEL SCHÜLZGEN is a research professor and NASSER PEYGHAMBARIAN is a professor and chair of photonics and lasers in the College of Optical Sciences at The University of Arizona, Tucson, AZ 85721; e-mail: [email protected]; www.optics.arizona.edu.

Tell us what you think about this article. Send an e-mail to [email protected].