A simple and inexpensive process to fabricate specialty polymer optical fiber has been developed by Cristiano Cordeiro, a researcher and professor at the University of Campinas’s Physics Institute (IFGW-Unicamp) in the state of São Paulo, Brazil.1 Cordeiro created the process during a research internship at the University of Adelaide in Australia.

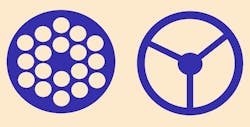

The procedure roughly resembles the extrusion method used to produce pasta: pressure is brought to bear on a ductile material so as to force it through a die, producing fiber with the appropriate inner structure. It can be used to fabricate not only all-solid core/clad fiber, but also microstructured fiber containing an array of longitudinal holes, including hollow-core fiber. To create the microstructures, the researchers used titanium dies fabricated via additive manufacturing using appropriate 3D printers.

“To simplify the fabrication of special optical fiber, we deployed equipment and techniques that are becoming more affordable and accessible thanks to the popularization of 3D printing,” Cordeiro says. “The only machine required is a compact horizontal extruder similar to the device used to produce filament for 3D printers. It’s about the size of a microwave oven and is far less costly than a draw tower. The titanium die with solid parts and holes is coupled to the extruder exit.

The process can be completed with bench-mounted equipment that’s at least 100 times cheaper than for the conventional process, and takes less than an hour from feedstock to end product, notes Cordeiro.

Source: https://pesquisaparainovacao.fapesp.br/brazilian_researcher_creates_an_ultrasimple_inexpensive_method_to_fabricate_optical_fiber/1549

REFERENCE:

1. Cristiano M. B. Cordeiro et al., Nature Scientific Reports (2020); https://doi.org/10.1038/s41598-020-66632-3.