HONG CHOI AND TONY BACARELLA

Increasing demand for high-performance, ruggedized microdisplays for defense applications is being driven by the integration of thermal imaging into man-portable soldier systems. As thermal imagers increase in performance and decrease in power, they have seen significant leaps in fielding volumes and are providing soldiers and law-enforcement agencies decisive advantages in battlefield operations and surveillance. A high-performance, high-resolution microdisplay is required to preserve the information acquired by the sensor and comply with the requirements for light weight and low power consumption while being exposed to the rigors of the military environment.

Microdisplays with typical dimensions of less than one inch on the diagonal are combined with lens systems to provide the viewer with a large virtual image. Currently deployed thermal-imaging systems incorporate monochrome microdisplays with VGA resolution—640 × 480—that is equivalent to or higher than the sensor resolution. Kopin has been supplying microdisplays for thermal weapon sights deployed by the U.S. Army since the Thermal Weapons Sight-I program in 1998.

The next generation of night-vision systems being developed by the U.S. Army will convert darkness into daytime-like scenes using multispectral imaging sensors and full-color displays. The improvements in these future systems will include higher resolution with full color and digitally fused images from multiple sensors. These detectors will be sensitive at different spectral ranges and the information will be processed, combined, and displayed to reveal features that are otherwise hard to see. To support such advanced features, microdisplays need resolution up to SXGA (1280 × 1024 resolution), high contrast ratio, wide dynamic range, low power consumption, and must operate over the full military temperature range.

CyberDisplay technology

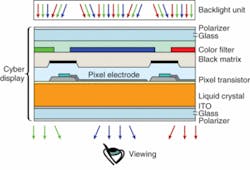

Kopin’s CyberDisplay family of microdisplays includes the world’s densest transmissive active-matrix liquid-crystal displays (AMLCDs), boasting the world’s smallest pixels. These pixel sizes are achieved while maintaining stunning image quality by use of high-quality single-crystal silicon transistors—in fact, the CyberDisplay microdisplay is the only transmissive AMLCD using single-crystal silicon transistors. To realize a transmissive display that is fabricated from opaque silicon wafers, we use patented technology to “lift off” the thin integrated-circuit (IC) layer from the silicon wafer and transfer it to a clear glass plate (see Fig. 1).

Recent progress in this technology has resulted in substantial reduction in power consumption, instant-on operation at cold ambient temperatures, and further reduction in pixel size. These improvements are the results of novel display circuit architectures and 8 in. wafer processing that utilizes smaller design rules and more advanced silicon IC processing technologies than does 6 in. processing.

Architecture improvements

Low-voltage (LV) architectures, advanced shift-register circuits, and thin-film internal heaters have substantially reduced display-system power consumption.

The LV architecture reduces the input-video voltage levels to half the typical values for other AMLCDs. Instead of the usual direct-current (DC) coupling of the input signal, Kopin’s LV architecture uses input coupling through capacitors to effectively double the voltage written to pixels. It also features integrated switch circuitry to restore the DC level, which is required for proper AMLCD operation. The reduced interface voltage swing of 3.3 V, together with its compatibility with complementary metal oxide semiconductor (CMOS) driver ICs, results in lower power consumption of the display driver circuits.

The new shift-register circuit dramatically reduces the power consumption of the display panel. In a conventional display, the 3.3 V clock signal goes through a level shifter and buffering stages to deliver approximately 10 V of clock signal to the shift register. The new shift register eliminates the need for these circuits and can be driven directly from the 3.3 V clock signal. The elimination of the level shifter and buffers reduces the power consumption of the new display panel to only about 10 mW compared to around 100 mW for conventional display panels.

Thin-film heater technology allows operation of the AMLCD at ambient temperatures as low as -40°C with nearly “instant-on” capability. This performance is achieved without the need for an external heater, significantly reducing display-system power consumption. The integrated thin-film structures nested in the backplane serve as an active-matrix element while simultaneously operating as an integral heating element. This dual-purpose mode of operation is available on demand and allows the display to provide full-video-rate performance at temperatures down to -40°C. Intimate contact of the thin film with the liquid-crystal material results in the ultrahigh heating efficiency and cold-start operation within seconds.

8-inch processing

The use of smaller-pixel transistors offered by 8 in. processing allows further shrinkage of the pixel size without reducing the light-transmitting aperture ratio within a pixel. The picture quality and power consumption are improved by using multilayer metallization available for 8 in. processing, which provides flexibility in routing the lines and reduces the resistance of and crosstalk between lines. Another benefit of 8 in. processing is planarizing each layer before stacking the next one, which results in a less complex structure around the pixel aperture. A simpler topology would reduce the side effect that lowers the contrast ratio.The CyberDisplay 640M LVR monochrome display with VGA (640 × 480) resolution combines all three architectural improvements described above and utilizes the advantages of 8 in. processing. The complete display system dissipates less than 130 mW during normal video-rate operation. At the -40°C ambient temperature, the display can be heated to 0°C within 10 s with total energy consumption of 10 J compared to 60 s and 84 J for an earlier VGA display with an external perimeter heater. This low-power operation, combined with the low-temperature instant-on capability, leads to improved battery life and battlefield readiness of soldiers.

Full-color SXGA displays are required for night-vision systems with image fusion utilizing multispectral sensor technologies such as forward-looking infrared (FLIR) and near-IR waveband sensors. Because Kopin’s CyberDisplay SXGA LVR display has approximately four million color dots, circuit routing and bandwidth requirements are too demanding for the 6 in. wafer design and manufacturing process. Color SXGA displays produced by 6 in. processing exhibit low contrast ratios and undesirable image artifacts; SXGA displays fabricated with 8 in. design and processing, however, exhibit very sharp, life-like images and are being delivered in sample quantities for systems integration for next-generation night-vision systems.

By using 8 in. processing, Kopin was able to shrink the color pixel size to 11.25 µm square (from the 14.1 µm square minimum for 6 in. processing), achieving the smallest color SVGA display (800 × 600 resolution) in the LCD industry (see Fig. 2). The CyberDisplay SVGA LVS microdisplay has the same size (0.44 in. diagonal) as Kopin’s current CyberDisplay VGA display, allowing it to utilize the same optics and housing developed for the VGA display. Compared to its SVGA display with 0.59 in. diagonal that consumes 100 mW, the SVGA LVS display has a 45% smaller area and consumes 30% less power.

Night-vision systems

Unlike legacy night-vision systems using image-intensifier tubes, IR and multispectral systems require displays to convert sensor data to an image of sufficient quality for the user to extract fine detail from the scene.The latest Thermal Weapons Site (TWS) program, called the TWS-II Bridge, will significantly enhance the night-vision capabilities of U.S. soldiers through the deployment of more than 150,000 TWS systems. The Bridge program uses the CyberDisplay 640M LVR monochrome VGA display with ultralow power consumption of less than 25 mW.

In addition to the TWS products, the U.S. Department of Defense is actively developing a variety of next-generation helmet and head-mounted night-vision equipment. In some cases, these systems will use the thermal imager as an augmenting spectrum to the visible spectrum. Systems will be developed using two primary modalities: optical image fusion and digital image fusion. The optical image-fusion system that is nearing fielding is the Enhanced Night Vision Goggle (ENVG), which fuses a green intensified image onto an amber IR image using an optical beam combiner (see Fig. 3). The two images are accurately registered both at the objective lens (boresighted) and at the beam combiner (aligned).

The U.S. Army is also developing a multispectral, digitally fused, full-color helmet-mounted system called the Enhanced Night Vision Goggle Digital, which uses the SXGA AMLCD and a low-power application-specific IC driver specifically for this program. These new microdisplays, in combination with multispectral sensors and image-fusion techniques, will enable soldiers to clearly see high-resolution sensor imagery during day and nighttime operations, providing crucial advantages in hostile environments.

HONG CHOI is chief technology officer and TONY BACARELLA is business development manager, government programs, at Kopin Corp., 200 John Hancock Rd., Taunton, MA 02780; e-mail: [email protected]; www.kopin.com.