A miniaturized sensor developed at the Georgia Institute of Technology (Atlanta, GA), which is claimed to be the first such device able to produce narrowband multispectral imagery in real time, now shows promise for video application. Because the design enables low-cost image acquisition in a single exposure, it paves the way for practical application of multispectral imaging in the field or at the point of care. In fact, the imaging group at Georgia Tech’s Center for Assistive Technology and Environmental Access (CATEA) has already gone through preliminary clinical trials to prove the device’s ability to detect erythema in patients with dark skin. Erythema, redness of the skin due to infection, radiation, and a number of other causes, is difficult to detect in highly pigmented skin.

Instead of using traditional filters or light-dispersion methods, the CATEA group devised a novel customizable filter mosaid. The filter can incorporate four or more wavelengths in the visual to near-IR range, each having a bandwidth of 30 nm or less. It can be etched onto a glass substrate (0.3 to 0.5 mm thick) and later integrated with CMOS and CCD sensors–or it can be deposited directly onto a glass layer (about 0.1 mm thick) on the image sensor, explains Linghua Kong, director of the Product Design and Development Department at CATEA.

Fabrication of the checkerboard-pattern filter array takes advantage of standard semiconductor lithography (using four or more masks, depending on the number of wavelengths desired) and vacuum multilayer film-deposition approaches. Three coating materials (titanium dioxide, aluminum oxide, and silver) combine to form the optical thin films.

To demonstrate the ability to integrate the filter with an image-sensor chip, the CATEA group chose a Mightex USB2 camera, which features either a monochromic CCD sensor with 4.65 × 4.65 µm pixels fabricated by Sony (Tokyo, Japan), or a CMOS sensor with 5.2 × 5.2 µm pixels produced by Aptina Imaging (San Jose, CA).

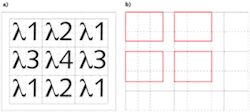

With pixel dimensions of 20.8 × 20.8 µm, the filter mosaic covers four filters with central wavelengths of either 460, 525, 577, and 650 nm (optimized to characterize bruising) or 540, 577, 650, and 970 nm (designed for detection of erythema; see figure). “We determine the dimension of the ‘new pixels’” based on the pixel size of the CMOS sensor, says Kong.

The camera generates raw data as 1280 × 1024 monochrome bitmaps. Each pixel value is an 8-bit integer from 0 to 255 representing the light intensity. Ideally, each filter unit, containing four wavelengths, will cover an area of 4 × 4 camera pixels (see figure, left). “We use the mean value of each masked pixel area as a single pixel in a newly generated image,” says Kong. “This means we generate four monochrome images with 320 × 256 defined new pixels.” The filter calculates the hue of each pixel in the multispectral image by averaging the four neighboring pixels in the new image. A Matlab-based program enables real-time processing and image display.

Enabling handheld devices

Although multispectral imaging has potential application in many fields, they have been very expensive–and have not been portable. Also, current approaches require either multiple exposures or extensive post-processing of images obtained. The CATEA group’s technology, developed with the help of funding from the National Institutes of Health, promises to facilitate commercial development of affordable handheld devices.

The approach has shown the ability to reveal invisible bruises or erythema on skin that might indicate developing pressure ulcers. Pressure ulcers are a serious concern for people with limited mobility and sensation, and are difficult to assess in persons with dark skin.