In conjunction with optical power meters and a polarization controller, tunable lasers are critical for in-process and final quality-assurance measurements of filter slope, isolation, polarization dependence, insertion loss, and reflectivity of optical-fiber-based multiplexers/demultiplexers, channel interleavers, wavelength-selective switches, and reconfigurable optical add-drop multiplexers (ROADMs) used in fiber-optic networks.

Cascades of ROADMs with different filter shapes accepting fast modulation-broadened signals place tight criteria on channel specifications in the manufacture of optical fiber components, leaving little to no room for measurement uncertainty. To ensure that these tight specifications are achieved, Keysight Technologies (Santa Rosa, CA) has developed a tunable laser intended for optical communications test and measurement applications that is capable of subpicometer tuning repeatability, even at full sweeping speeds up to 200 nm/s.

4X, 40X, and 15 dB improvements

Compared to its predecessor, the 81600B tunable laser module, the new 81606A has more than four times the absolute tuning accuracy and repeatability, sweeps 40 times faster in both directions without impact on accuracy, and has 15 dB more dynamic range.

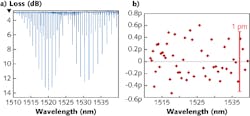

Tuning-accuracy improvements are achieved using a new wavelength reference unit with increased real-time tracking speed and resolution and an integrated gas cell for long-term stability and ±1.5 pm typical absolute accuracy (see figure). A new thermal design minimizes the environmental impact to the wavelength accuracy and power stability by compensating for residual temperature effects.

Tuning repeatability is ± 0.3 pm, independent from sweep speed and sweep direction, and reaches ± 0.2 pm in static mode with the help of an active tuning control loop. Mode-hop-free operation is standard across the full tuning range since the cavity resonator length and grating angle are changed simultaneously, which prevents phase slips.

For both wavelength options (1450–1650 nm and 1490–1640 nm), tuning speeds now reach 200 nm/s while maintaining wavelength accuracy and power reproducibility. This is 40X faster than the previous model’s most accurate sweep speed (of 5 nm/s).

Thanks to enhanced feedback controls and drive mechanics for better acceleration and sweep linearity the new model needs only 5 nm to accelerate to 200 nm/s, where previously 20 nm were required to get to 80 nm/s maximum speed.

Dynamic range has been significantly increased by using a higher-power source laser as well as a new cavity and laser-module design. The new gain chip’s power level is +11 dBm across the C- and L-band (peak power is +12 dBm) and a beamsplitter helps reduce source spontaneous emission (SSE) to 90 dB/nm. For example, in a measurement of the crosstalk between two adjacent channels of a dense wavelength-division demultiplexer measured with the N7747A power meter at 50 nm/s, filter details to 100 dB dynamic range can be uncovered.