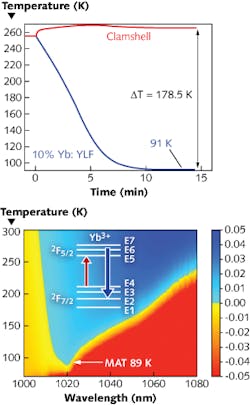

When laser light tuned to energies below the mean fluorescence energy of a material is absorbed, followed by efficient fluorescence generation and escape, outgoing photons remove energy via phonon annihilation and cool the material being illuminated. Having been the first team to achieve laser cooling to a cryogenic (<123 K) temperature of 119 K, researchers at the University of New Mexico and Air Force Research Labs (both in Albuquerque, NM) have now identified a way to approach the cooling temperature of liquid nitrogen (77 K) by reducing parasitic heating losses and maximizing the absorbed laser power.

First, the team sourced higher-purity crystal growth materials, resulting in a crystal grown with a background (parasitic) absorption coefficient that is half the value previously achieved. Second, a nonresonant cavity in the shape of a ring increases the absorption path length through the cooling crystal. Here, increased pump light passes through the visible cross section of the gain crystal (approximately 3 mm2) thanks to a smaller mirror separation that allows 22 passes through the crystal (an increase of 8 passes), resulting in pump power absorption nearly 42% higher than the previous geometry. These improvements allowed the researchers to achieve a record cooling temperature of 91 K in a 10% ytterbium-doped yttrium lithium fluoride (Yb:YLF) crystal. To reach the liquid-nitrogen temperature, the team is testing new active rare-earth ions in purified crystalline hosts, as well as developing new laser sources. Reference: S. Melgaard et al., SPIE Newsroom online, doi:10.1117/2.1201503.005790 (Mar. 13, 2015).