Jacques Albert, a professor in the Department of Electronics at Carleton University (Ottawa, ON, Canada) has received a $462,000 Strategic Project Grant from the Natural Sciences and Engineering Research Council of Canada (NSERC) to develop a new optical-fiber-based method of frequency conversion of light and other nonlinear-optical operations on light.

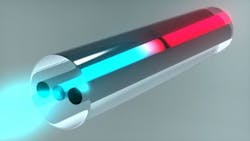

The aim is to create a silica-based fiber with a radially periodically poled structure consisting of, for example, alternating germanium (Ge)-doped layers; the fiber could produce second-harmonic generation (SHG) with high efficiency. Such a device, when paired with fiber lasers, would enable all-fiber visible laser sources, eliminating the large size and complexity of SHG systems based on bulk optics.

Albert and his colleagues have quite a bit of experience already in creating silica-based periodically poled silica micro- and nanostructures; over the past four years, they have designed and fabricated poled silica structures, consisting of layers of alternating dopant concentration on a flat substrate, and determined their performance. In one example, a 3-μm-thick stack of 75-nm-thick layers of alternating undoped and Ge-doped silica produced SHG that was 200 times more intense than possible with unlayered samples. The structure had an optical nonlinearity with a magnitude comparable to that of the widely used lithium niobate.

The Carleton group would like to take this technology and, rather than create flat films, create radially layered films that form a periodically poled silica fiber. Such a fiber could be easily spliced to a fiber laser—leading to what Albert calls “the next logical step in the evolution of modern fiber lasers.”

Poling at interfaces

The team that has been assembled for this project includes members from the Centre d’optique, photonique et laser (COPL) at Université Laval (Québec, QC, Canada) and Carleton University. Specialty-fiber producer CorActive (also in Québec) will be working with the group to produce a prototype doubling fiber that will be incorporated into a fiber laser, with the aim of producing a mode quality of a typical fiber laser.

“The field of poling had been dormant for about 10 years after a flurry of activity in the late 1990s, on the promise of glass-based doublers and electro-optic modulators,” says Albert. “It fizzled away because it was demonstrated by many groups that the effective nonlinearity in poled glass was clamped at a value that was too small for most applications.”

However, in 2003 at the OSA Topical meeting on Bragg Gratings, Photosensitivity, and Poling (of which Albert was the program chair), Steve Brueck from the University of New Mexico (Albuquerque) gave a talk in which he showed that, for a single deposited film on a substrate, attempts to measure the thickness of the poled layer were always “unresolved,” in the sense that as the measurement resolution was increased, the poled layer thickness appeared thinner and thinner, pointing to an effect arising at the interface instead of in the bulk of the film.

This “aha” moment for Albert got him thinking about stacking up layers to create an artificial crystal made of glass. “It took a few years to realize this in practice, but it worked amazingly well,” he says.

“We are now crossing our fingers that a fiber version can be fabricated and be usable (that is, have the nonlinearity without excessive losses),” he adds. “Since we will be using pure silica with weak germanium doping, there is hope.”

The project will consist of four steps. First, a station for testing multilayer periodic poling will be rebuilt and optimized and first calibrated with lithium niobate samples. Next will be the development and optimization of multilayer structures fabricated via both plasma-enhanced and low-pressure chemical vapor deposition (LPCVD and PECVD). The design, development, fabrication, and testing of the multilayer-core fiber will follow. Finally, a frequency-doubler prototype will be created to be fused with a 1.06-μm-emitting fiber laser. Stability, for example against the heat and fiber-laser light, will be tested. The final result will be a rugged all-fiber emitter of green light.