By combining light generated at different wavelengths from different continuous-wave (CW) laser diodes, researchers at the University of Southampton (England) can create trains of arbitrarily shaped optical pulses.1 The technique could be useful in telecommunications, metrology, sensing, and materials processing.

In the technique, five laser diodes with wavelengths ranging from 1548.8 to 1552.6 nm are phase-locked to the same optical-frequency comb via injection locking, ensuring mutual coherence; the optical power and phase of each laser diode is separately controlled to customize the waveform, which repeats at a 100 GHz rate. The five relative laser frequencies are spaced as follows: +300, +100, 0, -100, and -300 GHz.

The process can be considered the reverse of creating a frequency comb from ultrafast laser pulses. To create a frequency comb, a train of identical laser pulses (the input) spaced equally apart in time produces a frequency comb (the output), which is a group of spectral lines spaced equally apart in frequency; the shape of the pulses determines the distribution of power in the individual teeth of the comb. In the Southampton technique, five selected teeth in a frequency comb (the input) lead to a train of identical shaped pulses spaced apart equally in time (the output).

Both techniques are examples of Fourier synthesis, which takes advantage of the fact that the temporal and spectral qualities of a light beam are intimately related. This allows the deliberate tailoring of an input parameter (temporal or spectral), which produces an output parameter with the desired qualities (spectral or temporal, respectively).

Phase, intensity, polarization control

In fact, to create the input for their experiment, the Southampton researchers began with an erbium-doped fiber mode-locked laser that produces a frequency comb, which is demultiplexed using an arrayed waveguide grating (AWG). Five “slave” laser diodes are then phase-locked to the five selected teeth of the comb; varying the intensities and relative phases of the five laser diodes using variable optical attenuators (VOAs) allows the researchers to tailor the pulse shapes in the output train. In addition, polarization controllers (PCs) between the mode-locked laser and the slave lasers ensure that the polarization of the slave signals are aligned to that of the output of the mode-locked laser.

A small portion of the output from the laser diodes is tapped off for an electronic feedback loop that helps maintain the injection-locking. The rest of the light from the five diodes is fed through additional VOAs and PCs, as well as fiber-stretch-based phase shifters; all laser-diode light is then combined in another AWG.

Additional active relative-phase stabilization was needed after multiplexing in the AWG, due to thermally induced variations in the connecting optical fiber—a somewhat cumbersome technique using an erbium-doped fiber amplifier (EDFA) frequency shifted by 35 MHz by an acousto-optic modulator (AOM), followed by injection back into the original comb modes, along with electrical low-pass filters and radio-frequency phase-shifters. However, the researchers note that much more elegant solutions do exist, such as digital phase-locked-loop techniques.

Tailoring the pulse profile

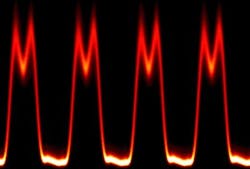

After measuring and calibrating the setup, the researchers began by creating a spectral form with a sinc-function-shaped envelope, which leads to approximately square-shaped pulses (see figure); the shape is not exactly square due to the fact that the five lasers can only roughly approximate a sinc function (in addition, there was a slight mismatch between the measured and targeted relative phases). Other pulse shapes could be readily produced, including true flat-top pulses with rounded edges and waveforms with a sinc2 spectrum, which result in a pulse train shaped as sections of parabolas.

“As our new technique is based on a different approach to that currently used, it has several distinct features that are relevant in many applications,” says David Wu, lead author of the study. “First, it is easily scalable—by combining a larger number of input lasers, shorter or more complicated-shape pulses and/or more power can be obtained. It can also generate pulses with a very low level of noise (down to the quantum limit) and very high (greater than 1 THz) repetition frequencies. Finally, it consists of miniature and low-cost semiconductor lasers that can all be integrated on the same chip, making our pulse generator potentially very compact, robust, energetically efficient, and low cost.”

“We believe that this work is likely to be of direct interest to scientists working in virtually any field of optics where pulsed laser sources are used,” adds Radan Slavik, who leads the research group. “We also believe that the concept and phase-locking technology developed could be widely applicable with the broader optics/photonics community.”

REFERENCE

1. D. S. Wu et al., Optica 2(1), (Jan. 2015); http://dx.doi.org/10.1364/OPTICA.2.000018.