While direct modulation of a semiconductor laser’s drive current enables fiber-optic communications at speeds of around 2.5 Gbit/s, higher-speed operation using direct modulation has historically been confounded by frequency chirp, forcing commercial 10 Gbit/s systems to use an external electro-optic modulator. For increased capacity (100 Gbit/s and beyond), coherent systems were recently commercialized that also use external electro-optic modulators to deliver complex modulation formats.

New research from the University of Southampton’s Optoelectronics Research Centre (ORC; England) and Eblana Photonics (Dublin, Ireland), however, has skirted this historical limitation through a modulator-free, optical-injection-locking method that brings the benefits of direct modulation back to the modern coherent telecommunications network.

Modulator limitations

Today’s high-speed in-phase-quadrature (IQ) modulation formats (such as quadrature amplitude modulation, or QAM) are modulated on an optical carrier using expensive, bulky, and difficult-to-integrate lithium niobate (LiNbO3) IQ modulators. While indium phosphide (InP), silicon (Si), and gallium arsenide (GaAs) modulators are currently being researched, their performance is poor compared to LiNbO3.

The Southampton modulation-free scheme uses optical injection locking (OIL) and direct modulation to enable high linearity, reduced power consumption, small footprint, easy integration, and cost-effective QAM transmitters. Direct modulation can also benefit any nontelecommunications applications that depend on controlling the phase properties of laser beams, such as coherent beam combination in fiber lasers.

IQ signal generation

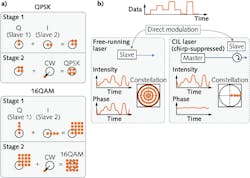

First, three lasers are made coherent through OIL by locking two of them with the third one. Subsequently, the two optically injection-locked lasers are directly modulated with two independent data streams (representing I and Q). These two amplitude-modulated lasers are then combined (with their carriers 90° shifted with respect to each other) and interfered destructively with a master signal to remove the optical carrier part of the signal, thus generating QAM modulation. This OIL process not only makes the three lasers mutually coherent, but also suppresses modulation chirp. It can also significantly increase the modulation bandwidth to values up to 80 GHz.

In a proof-of-concept experiment, two optically injection-locked, directly modulated lasers (simple Fabry-Perot lasers) allowed—with help from temperature tuning—operation over almost the entire telecom C-band from 1530 to 1560 nm (see figure).

“Our work highlights the exquisite control that we have achieved over the optical field generated directly from a current-modulated semiconductor laser,” said Radan Slavik, principal research fellow at the ORC leading the research. The team aims to commercialize the technology.

REFERENCE

1. Z. Liu et al., Nat. Commun. 5, 5911 (Dec. 2014); http://dx.doi.org/10.1038/ncomms6911.