Rice University (Houston, TX) researchers have developed a simple, single-step and scalable method to create graphene films from carbon polymer sheets using a carbon dioxide (CO2) laser. Amenable to roll-to-roll manufacturing, the laser-induced graphene (LIG) process can create highly conductive interdigitated electrodes, for example, with capacitance values greater than 4 mF/cm2 and with 9 mW/cm2 power density for use in microsupercapacitors. This high conductivity (which is comparable to that in competing carbon-based microsupercapacitor technologies) is possible, the researchers surmise, through the unusual pentagon-heptagon polycrystalline lattice

of the LIG films.

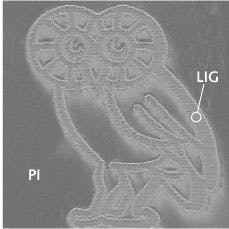

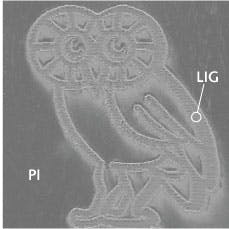

The polymer that converts to graphene best using the laser-induced process is polyimide. As the laser “writes” a pattern in the polymer, graphene flakes containing defects with five-, six-, and seven-atom rings form on the surface of the polymer. To demonstrate the ease of the process, the researchers were able to write a graphene image of the school’s mascot, an owl (see figure), into the polymer. The graphene structure, which is about 20 μm thick, is not as conductive as copper, but is adequate for a variety of power-charging applications. Reference: Jian Lin et al., Nat. Commun. 5, #5714 (Dec.10, 2014).