JAMEY BUTTERIS

One of my favorite technical authors as a young adult was Stephan Hawking. A Brief History of Time was a great entertaining read on a long winter's day in Chicago. Solid-state lighting (SSL) has had a much shorter history and is just as entertaining. Consider that in 2004, light-emitting diodes (LEDs) for lighting were a curiosity and most lighting companies were bending and painting sheet metal with little knowledge, or care, for the world of electronics.

During this time, terms like efficacy, chromaticity, color-rendering index, and correlated color temperature were barely known and even less understood. After all, the lamp manufacturers took care of those details. Electro-static discharge (ESD) was a four-letter word. Photometric testing used a relative standard where the source lumens were entered into the report by the testing technician. "What do you mean 'what is the lumen value for my LED fixture?' Isn't that what you are measuring?"

Fluorescent lighting efficiencies were formidable and, with a traditional troffer with 3000 lumens at 85+ lumens per watt (lm/W) and a cost of $30 compared to a 600 lm LED downlight barely capable of 25 lm/W costing more than $100 to manufacture, seemingly insurmountable. To escalate the situation further, a few of the component companies making the LEDs threw down the gauntlet and challenged the lighting companies to change or become as obsolete as the light sources they were using.

Fortunately, luminaire manufacturers accepted the challenge. Armed with tools like payback calculators, the Department of Energy Solid-State Lighting (DOE SSL) program, Caliper, and Energy Star, and guided by various institutions for higher education, we adapted and have come a long way in the last 10 years. The first LED fixtures designed were LED versions of the same fixtures that used traditional sources. Today, luminaires are being designed "around" LED technology to maximize its benefits—all very entertaining in hindsight, but a bit daunting while living through it.

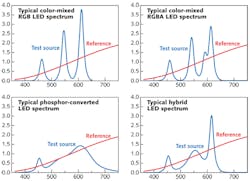

White-light LED options

As we know, white light is a composite of many wavelengths within the visible spectrum. There are several ways to accomplish creating this spectrum using LEDs (see Fig. 1). The dominant technique used today is the phosphor-converted LED, mainly from a blue die with the phosphor in direct or indirect contact with the emission surface itself. The second means is adding narrowband emitters to create the same effect, but with more specific gaps in the visible spectrum.But a more current trend for creating white-light LEDs is by exploiting red/green/blue (RGB) LEDs using RGB(A) and RGB(A)+blue/phosphor conversion (PC)—a means by which the optical spectrum is enhanced through amber RGB(A) or other narrow wavelength emitter, or RGB(n). In some designs, this spectrum enhancement is in addition to using a PC LED as the primary light source, and the extra spectral components are used to alter the mood of the light rather than create drastic changes in color. Effects like simulating noontime Sun or a sunset have been demonstrated.

This RGB option is starting to see more traction for luminaires that use color mixing chambers that allow the spectrum to be mixed and homogenized inside the fixture or where surfaces exist that allow blending on the fixture's emission surface. In either case, the effect is to show a uniform light source absent of chromatic separation. This is in addition to the established technique that uses a red + PC LED where the spectrum is enhanced with a red component but the overall color temperature remains fairly consistent over the life of the fixture and does not change color based on a control input. Here, the intent is to increase to color quality further and create a source that mimics more natural daylight. When added to a fixture with integrated controls, this newer technique begins to address the desire for an ideal lighting space that adapts to real-time lighting requirements.

Overall, these latter RGB and red + PC methods represent an interesting trend. However, in the long term, multispectral emitters and PC + RGB options may become the best choice and largely—or in whole—bypass phosphor conversion only. In addition, these options have the added benefit of being able to tune the output of the fixture to the most desirable color.

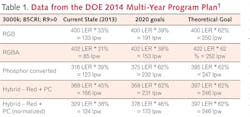

A current data point from the DOE 2014 Multi-Year Program Plan (MYPP) for the 2013 Hybrid Red + PC LED option shows a higher efficacy than the other options in the chart (see Table 1). Here, luminous efficacy radiation (LER) is the practical measured value, and LER(max) is defined as the theoretical luminous efficacy per optical watt of input. The ratio of LER/LER(max) is shown as a percentage that represents the real or expected value, and is multiplied by the maximum theoretical lumen output to indicate the practical lumen per watt efficacy.The DOE MYPP roadmap defines the 2020 luminaire LED goals. As the industry has been tracking these targets reasonably close, they are attainable within the timeframe identified with many of the improvements already in development. The theoretical goal represents the maximum potential that may or may not be attainable, given the state of the art today.

As with any theoretical maximum there may be elements that are unable to be overcome due to practical, real-world issues. Using data from the chart elements for RGB and PC and assuming a 15% added single spectral red content, the adjusted, weighted (normalized) numbers for the various options show that long-term, theoretical LER for all of the presented methods will become statistically equal. However, if the 2020 goals are the maximum practical results that may be achieved, then the PC LED and Red + PC will emerge as the clear leaders. Any gains that Red + PC technology may have enjoyed for the past five years will have been erased by improvements in the LER for PC LEDs.

The best approach

Applied to a luminaire, the simplest LED technology approach may end up being the most favored and likely adopted en masse. The simple PC LED that does not need to incorporate a complicated control system may be the simplest choice for lighting applications. Lighting designers and architects are asking for fixtures that make the spaces they create increasingly relevant. This often means having color-changing features or integrated control systems.

There are tense moments when a conflict emerges between bulk light output, lowest cost, energy savings, and more advanced LED control options that can change colors or interact with their environment. This divergent market trend will be more pronounced in the coming years, and this conflict will also impact how LED upgrades are prioritized by the component suppliers. If an RGB(n) tunable fixture has a better economic trend over a PC LED with a single color point, then we will see more product offerings based on RGB(n). Certainly, we expect that the next five years will be an exciting race between these two methods.If this trend continues to 2020 with little gain in efficacy and no major technology improvements, then the PC LED may lose its lead against RGB(n), especially if component costs for RGB(n) can be improved along with the trend for integrated controls. Color changing would transform from a mere curiosity and high-end option into a useful choice for more everyday applications.

Challenges for luminaire LEDs

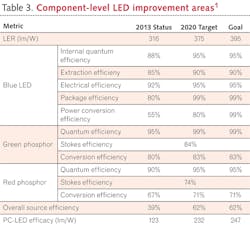

Despite continued improvements in LED efficacy, more potential gains are possible with the blue LED die itself (see Table 3). With a total power conversion efficiency today of 55% and a 2020 goal of 80%, this is the single biggest improvement potential—most of the gains are in within the LED package itself. This portends more package choices on the horizon and possible larger die sizes to improve current densities. All of this is possible with existing solid-state technology and with continued investment in manufacturing processes.But even the best-designed LED component can suffer in a poorly designed luminaire. Typical design efficiencies for a luminaire are as follows: 70–95% optical efficiency; 75–98% driver efficiency; 94–115% current density effects (reduced current density below 35A/cm2 allows >100%); 86–93% thermal efficiency; and 71–88% overall fixture efficiency.

Most of the subsystems for an LED luminaire are now well understood. As LEDs become more efficient at using electrical energy, they emit less in the form of heat. This has allowed the system heat sinks to be optimized, and in some cases, removed. Larger die upgrades or form factor changes force optics to be redesigned or drastically altered, and possibly eliminated.

Increasingly popular, direct AC systems eliminate the traditional power conversion driver, but require LEDs capable of higher pulse currents and phosphors capable of slow decay as well as high voltage containment to ensure safety compliance. Low-voltage DC LED systems will continue to make best use of photovoltaic conversion and/or battery-backed systems.

As LED component pricing continues to improve, its impact on a bill of material will become less and less. What continues to see the need for refinement within a fixture is the use of integrated controls and better use of power.

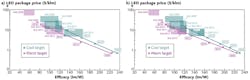

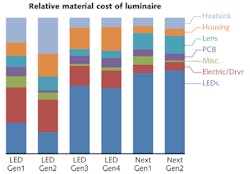

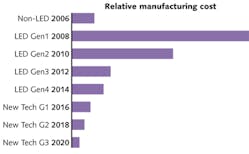

Finally, next-generation LED luminaires must continue to take advantage of lower-cost materials and system needs (see Fig. 3). For example, in a 600 lm downlight, the traditional "can" is included in the material cost of the system; that is, the biggest impact on the cost of the fixture for Generation 3 was the elimination of the AC to DC driver in favor of a direct AC approach. The trend shows that as system components are reduced, some can be eliminated.Luminaire LEDs will continue to make measurable technological advances with an anticipated 50% reduction in price and a 20% improvement in efficacy over the next two years with substantial improvements identified for use by 2020. Solid-state technology has come a long way with a reasonably well defined future ahead of it.

REFERENCE

1. All tables and figures are sourced from the 2013 and 2014 Department of Energy Solid State Lighting Research and Development Multi-Year Program Plan (DOE MYPP); see http://1.usa.gov/1pvZxiB and http://1.usa.gov/1GtW0Nx, respectively.

Jamey Butteris is director of research at Hubbell Lighting, 701 Millennium Blvd., Greenville, SC 29607; e-mail: [email protected]; www.hubbelllighting.com.