DOMHNAILL HERNON and RYAN ENRIGHT

Energy demands are becoming a bottleneck across multiple industries. From reducing the energy costs associated with operating a building to maintaining the exponential growth of high-speed networks, energy considerations are critical to success. The need for improved energy efficiency is driving research to design and implement new technologies in a scalable and energy-efficient way.

Bell Labs Alcatel-Lucent founded the GreenTouch consortium, an organization for researchers dedicated to reducing the carbon footprint of information and communications technology (ICT) devices, platforms, and networks. The goal of GreenTouch is to deliver and demonstrate key components needed to increase network energy efficiency by a factor of 1000 compared with 2010 levels.

The Thermal Management and Energy Harvesting Research Group at Bell Labs (Dublin, Ireland) leads Alcatel-Lucent's longer-term research into electronics cooling and energy-harvesting technology development. It has created new energy-saving approaches that promise significant savings; one research project is targeting between 50% and 70% energy reduction per bit by improving the thermal management surrounding the photonic systems by means of which laser light transmits data through fiber-optic communication networks.

From macro to micro TECs

The explosion in data traffic in the last few years is causing an immense strain on the current network, which was designed for low cost and coverage rather than energy efficiency. Energy management is becoming a major obstacle to the deployment of next-generation telecommunication products.

To address this issue, the Thermal Management team investigates all aspects of electronics and photonics cooling. The research team is realizing benefits that affect product performance by using multiphysics simulation at multiple length scales from the micrometer scale to the macro level.

Today's photonics packages employ a large macro thermoelectric module that cools all the lasers to below ambient temperature. Thermoelectrics are used for fine temperature control, but they are highly inefficient. Each laser is tuned to a specific frequency via resistive heaters that are placed very close to each laser; each resistive heater immediately doubles the local heat flux around the laser, causing further thermal problems. So in today's thermal design of photonics packages, each laser is inefficiently cooled down just to be heated up again.

It is our view that this approach is not scalable, especially when considering the explosion in data traffic growth in the network, resulting in ever-decreasing package sizes and the longer-term requirement to move to silicon photonics, enabling ultimate integration for space saving and cost reductions.

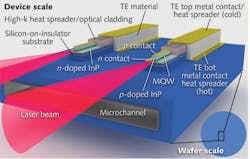

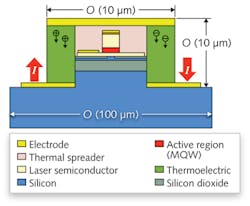

The thermally integrated photonics system (TIPS) architecture developed by the thermal team at Bell Labs aims to develop the thermal component building blocks to enable integrated photonics that will scale to meet network growth requirements (see Fig. 1). In particular, our approach is to replace the large macro thermoelectric cooler (TEC) with individual micro TECs (μTECs) on each laser. Therefore, measuring and modeling the characteristics of each laser and individual μTEC becomes extremely important.

To find efficiencies at the micrometer scale, we used the COMSOL Multiphysics software package (COMSOL, Burlington, MA) to model potential approaches for thermoelectric cooling of photonic devices, simulating the electrical, optical, and thermal performance of new laser devices with μTECs (see Fig. 2). Such μTECs have the potential to be applied in telecommunication laser devices that require cooling to maintain their design output wavelength, output optical power, and data-transmission rates.Laser simulation & measurement

Thermal resistance is the key thermal parameter with the largest impact on a laser's performance in continuous operation. The thermal resistance of a laser, Rth, with units of K/W, describes the temperature increase in the laser above a reference substrate temperature versus the power dissipated by the laser and represents a standard measure of impedance to heat flow. Minimizing the laser thermal resistance is desirable to reduce the need to actively cool the device below the ambient temperature and thereby reduce the load on the thermoelectric.

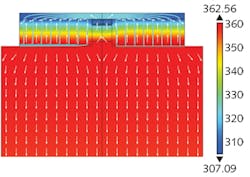

Challenges in cooling photonics devices (and in modeling them as well) include precise temperature control, extremely high local heat fluxes, and micrometer-size features that need to be cooled. Thermoelectric effects—Peltier, Thomson, and Seebeck—and the resulting temperature and electrical fields were all coupled within the same COMSOL simulation environment, providing deeper physical insight into the problem.

The length scales of typical lasers used in photonics devices range from micrometers to tens of micrometers; however, laser performance is coupled from that scale all the way up the thermal chain to the ambient air on the board. Solving complicated multiphysics problems across multiple length scales is computationally expensive; we used COMSOL software in combination with the MATLAB (MathWorks; Natick, MA) numerical computing environment to accelerate the design phase. This allowed accurate modeling of different parts of the package with design rules in MATLAB, providing computationally efficient insight into the role of system design on laser performance (see Fig. 3).We built a range of numerical models that accurately capture the physics around the lasers and within the photonics package. In order to benchmark the models against real devices, we had to perform detailed thermal measurements of the laser devices. In particular, measurements of the laser's thermal resistance provided a means to compare against experiment.

The laser's thermal resistance was determined by measuring the ratio of the change in output wavelength versus power dissipated in the laser (units of nm/W) during continuous-wave operation and the change in output wavelength versus the temperature in the active region (units of nm/K) during pulsed-wave operation. The ratio of pulsed and continuous characterization of wavelength shift with dissipated power and substrate temperature, respectively, provided an indirect measure of device thermal resistance.

This detailed measurement approach enabled the development of accurate simulations that compare well to the existing laser performance. We have built on this ability by exploring new thermal architectures that will provide enhanced thermal performance while not hindering the optical and mechanical performance required. We developed specialized numerical code that allows full 3D simulation of the μTEC performance while also capturing the performance of the laser itself.

The insights gained in performing detailed thermal measurements and simulations of photonics devices are proving invaluable, and new design concepts are being explored in more detail within our lab. We believe that the resulting new thermoelectric cooling methods should see commercial use in as little as five years.

Domhnaill Hernon is head of the Efficient Energy Transfer (ηET) Department and Ryan Enright is technical lead on the TIPS project at Bell Labs Research Alcatel-Lucent, Dublin, Ireland; email: [email protected]; www.alcatel-lucent.com.