Two researchers at the Microsystems Research Laboratory of Southern Methodist University (Dallas, TX) have created very small (110-μm-diameter) dome-shaped doped optical resonators that, when optically pumped remotely by a Q-switched Nd:YAG laser, lase and emit a comb spectrum that shifts depending on the temperature of the dome.1

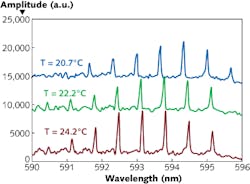

This means that the miniature sensors can be stuck onto walls or any other remote location, allowing the temperature of the location to be easily monitored from afar. The spectral shift is about 0.06 nm/°C, leading to a resolution of 1°C (the resolution was limited by the experimental setup and can be improved in the future).

The domes form circular whispering-gallery resonators, in which the excited modes are defined by paths that closely follow the edge of the circle. The resulting emission spectrum approximates a frequency comb.

Any change in ambient temperature will cause the resonator to thermally expand or contract as well as the thermo-optic refractive-index coefficient to change; the resulting change in path length shifts the wavelengths of the excited modes, shifting the comb’s spectral position.

Made of doped optical adhesive

The domes themselves are made of a Norland (Cranbury, NJ) UV-curing optical blocking adhesive doped with a solution of Rhodamine 6G and ethanol. The researchers created two types of domes, both by depositing a 50 μm drop of the adhesive-based solution on a layer of PDMS polymer: the first type had no added covering layer, while the second type had an additional thin layer of PDMS deposited on top.

The Q-switched pump laser produced a beam with a 1 cm diameter and pulses with a 10 ns duration at a rate of 10 Hz. In the experiment, the pump beam impinged on the dome from the top (along its axis of rotational symmetry). The signal light was collected by a lens and imaged onto the entrance slit of a spectrometer with a resolution of about 0.07 nm. Temperature changes were produced by an electrical resistor mounted under the dome’s substrate and connected to a variable-voltage power supply.

The resulting spectral comb spanned about 5 nm with 7 to 9 comb teeth, and was centered at about 593 nm for the embedded dome (see figure), and 597 nm for the bare dome. Both types of domes achieved similar temperature-measurement resolutions. Because the sensitivity is not a function of the microlaser’s configuration, the temperature sensors don’t require any calibration as long as the thermo-optic coefficient of the resonator is known.

According to the researchers, the ratio between the largest and the smallest measurable value of temperature, or the dynamic range, is about 10, but decreasing the size of the domes to 10 μm could increase the dynamic range to 100.

The sensor itself is mechanically flexible, potentially enabling temperature measurements on surfaces that flex, the researchers add.

REFERENCE

1. T. Ioppolo and M. Manzo, Appl. Opt. (2014); doi:10.1364/AO.53.005065.