Scientists at ENSTA ParisTech/CNRS/Ecole Polytechnique (Palaiseau, France) have made ambient air lase by pumping it with 800 nm femtosecond laser pulses. The 40-mm-diameter beam from the Enstamobile laser system at Ecole Polytechnique—which produces 50 fs pulses with energies up to 300 mJ—was focused by a 100-cm-focal-length convex lens, producing plasma filaments in air that emit a supercontinuum white light peaking at wavelengths mostly longer than 650 nm. Return light was filtered to remove the IR pump radiation and most of the supercontinuum, and then collected into a fiber spectrometer.

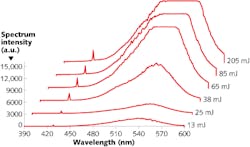

A pulse energy of 13 mJ resulted in a weak laser line appearing at 428 nm; as the pulse energy was increased, the line became stronger and shifted to longer wavelengths. At a pump-pulse peak power of 1.5 TW, the output of the air laser began to saturate. The measured width of the laser line was 1.2 nm, but that was likely limited by the spectrometer; the theoretical linewidth is likely on the order of 0.1 nm. The line is caused by the transition of nitrogen (N2) in the air from its second excited state to the ground state. The optical gain within the filament was estimated to be at least 0.7/cm, and likely much greater. The lasing radiation energy per pulse was about 2.6 μJ, with a conversion efficiency of 3.5 × 10-5. The effect could potentially be used in remote sensing. Contact Yi Liu at yi.liu@ensta‐paristech.fr.