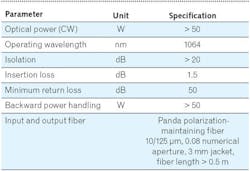

While traditional free-space fiber-pigtailed optical isolators can handle approximately 20 W of forward power and less than 1 W of backward power, an all-optical-fiber isolator with a nominal 1 μm operating wavelength from AdValue Photonics (Tucson, AZ) can handle more than twice the power in the forward direction and 50 times as much power in the backward direction. Because gain fibers amplify laser emission propagating in both directions, a backward-propagating beam can damage the laser’s upstream components, causing the laser to fail. Traditional isolators require a free-space beam to be launched from the isolator’s input fiber; the beam then propagates through several optical elements and is finally focused back into a separate output fiber. Any optical surface defects or optical misalignment in traditional free-space isolators (that typically use absorptive polarization filters to stop backward-propagating beams) can cause catastrophic fiber laser failure.

The new all-fiber isolator eliminates failure mechanisms through a Faraday polarization-rotating fiber with an extremely high Verdet constant that is fusion-spliced to two high-power fiber-based polarizers, completely eliminating any optical interfaces and removing all air gaps. The isolator can protect single-mode fiber lasers from 50 W throughput power in both directions. Contact Katherine Liu at [email protected].