Using an ultrafast picosecond pulsed laser, researchers at the Institute of Semiconductors at the Chinese Academy of Sciences (Beijing, China) have successfully formed laser-microstructured, dumbbell-shaped air voids inside the sapphire substrates of indium gallium nitride (InGaN) light-emitting diodes (LEDs) that improve the light output power of packaged devices by 24.7%. The noncontact technique, which increases light scattering at the sapphire/void interface, borrows from other light-enhancing methods that up to now have been achieved using more-complicated laser micromachining or nanostructuring techniques.

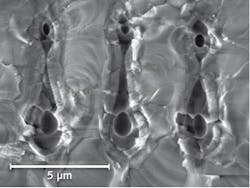

The voids are fabricated using a 1 W, 1064 nm laser with 15 kHz repetition rate and 50 ps pulse duration focused at a depth of 100 μm in roughly the center of the sapphire substrate. Analysis of the sapphire structure using microscopy and far-field radiation patterns showed vertically stacked air voids with upper and lower diameters of 1.2 and 0.5 μm, respectively. A ray-transfer matrix analysis reveals that the dumbbell shape is the result of a local change in refractive index at the first void location that creates a secondary focus effect of the laser beam that in turn creates the second void. In addition to increased light output from the rapid and inexpensive process, leakage currents were slightly lower for the air-void devices compared to conventional devices, meaning that the process does not degrade the electrical performance of the LEDs. Contact Xiaoyan Yi at [email protected].