When using a CO2 laser in aesthetic and therapeutic applications, 40% of the laser’s energy ablates human tissue while the other 60% causes the tissue to coagulate. This effect is universal even when using different fluence and pulse parameters, because CO2 laser energy is not completely absorbed by water in the skin. Much of the energy is reflected and refracted within the skin and heats the tissue instead of vaporizing it. Scientists at Sciton (Palo Alto, CA) have demonstrated, however, that erbium yttrium aluminum garnet (Er:YAG) lasers—due to extremely efficient absorption by water in the skin—allow doctors to control the level of ablation and coagulation separately to get the desired application outcome.

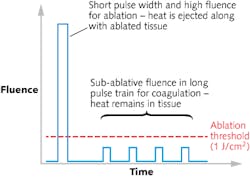

Sciton’s tunable Er:YAG laser has adjustable fluence and pulse width for independent selection of the ratio of ablation and coagulation. Ablative pulses with a fluence of more than 1 J/cm2 can vaporize any depth of tissue from 4 to 200 μm per pass with extreme precision, leaving no thermal energy behind. If coagulation is desired, sub-ablative laser energy is delivered in a train of pulses with <1 J/cm2 energy that heat the tissue to a selectable depth without vaporizing it. For example, a supra-ablative pulse (well above the ablation threshold) can vaporize tissue to a controlled depth for removing wrinkles, lesions, and acne scars externally, followed by a train of coagulative sub-ablative pulses that raise the tissue temperature and internally stimulate the dermal collagen matrix to firm the skin and add resilience. Contact Rick Mendez at [email protected].Sponsored Recommendations

Sponsored Recommendations

Request a free Micro 3D Printed sample part

April 11, 2024

How to Tune Servo Systems: The Basics

April 10, 2024

Voice your opinion!

Voice your opinion!