The adaptive-optical Giant Magellan Telescope (GMT), which will be located on Cerro Las Campanas in Chile and reach the “first light” stage by 2020, will have a primary aperture of 24.5 m and a resolving power 10 times that of the Hubble Space Telescope. The GMT’s field of view will contain movable fiber-optic light pickups to be placed at the images of specific stars; however, the potentially great number of these pickups (up to 400) makes conventional pick-and-place robotics far too slow in reconfiguring the pickup placements.

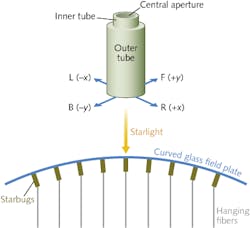

To allow rapid pickup reconfiguration, engineers at the Australian Astronomical Observatory (Epping, Australia) have developed small (20 to 30 mm tall) robots that they call “Starbugs”; each Starbug is made of two piezoceramic tube actuators joined at one end to form a pair of concentric “legs.” When the actuators are electrically driven, the pickup-holding robot dances along the chosen axis (x or y), taking steps only a few microns long, moving very precisely but at speeds of up to a few millimeters per second if needed. The herd of Starbugs actually operates upside down (or sideways if the telescope is pointed toward the horizon), hanging from a field plate, held there by a hose-supplied vacuum supply that evacuates only the concentric space between the legs. The entire Starbug array can be reconfigured in minutes. A 400-mm-diameter test rig with 20 Starbugs showed a maximum reconfiguration time of 196 s. The field plate for the GMT will have a diameter of 1.3 m. Contact James Gilbert at [email protected].