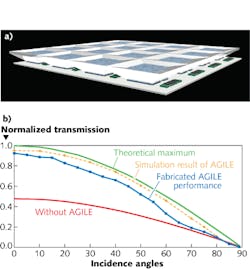

Researchers at Stanford University (Stanford, CA) have designed and fabricated an efficient axially graded-index lens (AGILE) solar concentrator that accepts sunlight from all angles (which allows it to operate even in diffuse light), eliminating the need for tracking the sun. AGILE can achieve passive concentration for solar incidence angles from the full 2π steradians (180°) of the sky compared to less than tens of degrees for a typical compound parabolic concentrator. In fact, AGILE’s simulated and experimental performance matches closely with the nontracking theoretical maximum cosine theta incidence limit.

In the AGILE concentrator, light enters the system through a larger aperture of low refractive index, goes through a graded-index material, and is then absorbed in a high-index material with smaller aperture. AGILE is a reversible system that can work both as a concentrator or a diffuser. For an air (refractive index of 1) to silicon (index of 3.5) concentrator, for example, the theoretical concentration factor—the square of the refractive index ratio (3.5/1)2—is 12.25, but the architecture is not limited to these values. Higher concentrations of even tens of Suns can be achieved with alternate materials and lower than the full 180° acceptance angles. A first demonstration of AGILE using transparent UV-curable polymeric materials ranging in index from 1.4 to 1.6 and apertures that decreased from 7 to 5 mm (accepting almost all 2π incidence angles) improved efficiency by a concentration factor of 2. AGILE reduces the active solar-cell area and hence cost, provides perfect antireflection and encapsulation, allows cells to be spatially separated to provide space for circuitry and heat sinks, and can be fabricated to conform to curved surfaces as well. Contact Nina Vaidya at [email protected].