Recent advances in nitride semiconductors are filling a crucial green gap in the spectrum of diode light sources. Laboratory demonstrations have pushed continuous-wave (CW) nitride laser diodes to wavelengths as long as 536.6 nm, which are attractive for green sources in picoprojectors but still shorter than the 550 nm peak of human visual sensitivity. Meanwhile, improvements in green nitride LEDs are supporting new options for solid-state lighting and other applications.

The green diodes are based on the GaN technology developed in the 1990s for blue laser diodes. Adding indium reduces the bandgap of GaN and shifts its emission to longer wavelengths, but adding too much indium can create defects because its atoms are larger than Ga atoms. This problem stalled development of long-wavelength InGaN diodes at 488 nm for a few years until developers found ways to grow good InGaN containing about 28% In, corresponding to wavelengths of 520 nm. Commercial versions are now available, and advances continue. In July 2012, a team from Sumitomo Electric's Semiconductor Technologies R&D Laboratories (Osaka, Japan) and Sony's Advanced Materials Laboratories (Kanagawa, Japan) pushed even deeper into the green, demonstrating CW output above 100 mW at wavelengths to 532.1 nm, and lower power to 536.6 nm. InGaN LEDs have also advanced to longer wavelengths, and like green laser diodes are opening new application possibilities.

Color vision and projectors

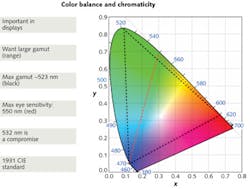

Green light is at the center of the human visual spectrum, making it crucial for color perception. The color range, or "gamut," of a laser projector depends on the spacing of the laser wavelengths. The gamut is represented by the area enclosed by lines drawn between the three laser wavelengths on the chromaticity diagram in Fig. 1. As can be seen, the color gamut depends strongly on the choice of green, but the red and blue wavelengths have little impact. Green sources emitting at 520–535 nm usually are considered to give the best gamut. Doubled neodymium lasers fall in that range, but developers prefer diodes because they are smaller and more efficient, can be modulated directly, and have lower coherence and thus less speckle.

A complication for displays is that the eye's sensitivity peaks at 550 nm. That means that developers must trade off between the higher efficiency of 550 nm sources and the better color possible at shorter wavelengths.

Nitride diode material issues

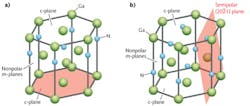

Indium gallium nitride lasers emitting at wavelengths to about 515 nm are grown on the hexagonal c-plane of a GaN substrate. The c-plane structures are highly polar, with electric fields that separate electrons and holes—an effect that decreases the bandgap, allowing emission at longer wavelengths than otherwise possible with the same In concentration. However, the polar fields also reduce recombination rate and laser emission efficiency. The rectangular m-planes on the sides of the hexagonal structure are nonpolar, but diode fabrication is so difficult on that plane that little work is being done on green lasers.Some long-wavelength green laser developers have turned to an alternative approach, growing structures on a semipolar plane, oriented at an intermediate angle to both the c-plane and the crystal axis, as shown in Fig. 2. Diode growth is relatively easy on a semipolar substrate, and efficiency is higher than on a polar substrate because the electrons and holes are close. However, a few percent more In must be added to produce the same wavelength as a polar diode, increasing the defect problem. An excellent recent tutorial gives details.1

Both polar and semipolar approaches "have big challenges, but those challenges can be solved," says Uwe Strauss, director of semiconductor development at Osram Opto Semiconductors (Regensberg, Germany). "Today it is still an open challenge which approach will result in the best product." He notes that substrate cost is an important factor in product costs.2

Pushing beyond 530 nm

Sumitomo and Sony crossed the 530 nm barrier this summer by growing diodes on semipolar {2021} GaN substrates, which they found eased the growth of homogenous InGaN quantum wells. Grown by hydride vapor-phase epitaxy, their semipolar GaN substrates had fewer than a million threading dislocations per square centimeter of surface and resistivity low enough to place ohmic contacts on the back. The fabricated lasers with multiple quantum wells 2–3 nm thick on the substrates, etched a 2 μm ridge waveguide into the structure, and cleaved mirror facets to form a 500 μm cavity, coated on one end with a 50% reflector.

They used that structure to make CW InGaN lasers emitting from 525–536.6 nm. Output was highest at the shorter wavelengths, dropping from 167 mW at 525.1 nm to 106 mW at 532.1 nm, the longest wavelength where output exceeded 100 mW. Output was 75 mW at 535.7 nm, but they did not report a power measurement for their record-setting 536.6 nm laser.3

"Improvement of the slope efficiency was the key factor for obtaining higher output powers," lead author Shimpei Takagi of Sumitomo wrote in an e-mail. They reported 4.7 V thresholds, well below the 6.4 V of earlier green lasers, and wall-plug efficiencies of 7.0 to 8.9%.

More good news came from a companion paper on lifetimes of semipolar green lasers emitting at 527–530 nm. After 1000 hours of operation, the Sony-Sumitomo team estimated the 50 mW lasers should last for more than 5000 hours.4 But Sony and Sumitomo said nothing about plans for products when they announced the results.

Product development and applications

Polar diodes can't match the laboratory records, but packaged versions are coming close. In July 2012, Osram reported singlemode output above 100 mW at 520 nm from a polar InGaN laser diode packaged in a TO-38 can at the International Symposium on Semiconductor Light-Emitting Devices.5 Slope efficiency reached 0.65 W/A, with a threshold current of about 50 mA.

Commercial singlemode green diodes in TO-38 cans are forthcoming, says Thomas Dobbertin, director of consumer lasers at Osram. The cans will be flattened on the edges so they can be packaged together tightly in light engines for flying-spot picoprojectors. A 30 mW version will emit at 510–530 nm; a 50 mW version will emit at 515–530 nm. Osram is focusing on those wavelengths because they offer a large color gamut for projection, which they consider the primary market, but they also are working on longer wavelengths for other applications.

Green nitride LEDs

The separation of electrons and holes in polar InGaN creates a slightly indirect bandgap, which is reduced by the separation of the carriers. As a result, Strauss says, LEDs emit on lower-energy transitions at longer wavelengths than in laser diodes with the same In content. In practice, that means that polar LEDs are easier to make at longer wavelengths than polar lasers. Steve DenBaars of the University of California at Santa Barbara (Santa Barbara, CA) and Soraa (Fremont, CA)—a developer of both nitride lasers and LEDs—has reported making green LEDs from both semipolar and nonpolar InGaN.

Green LEDs are used in low-intensity picoprojectors, but the big market for them is likely to be in tunable RGB lighting. Conventional solid-state lighting uses a single bright blue LED to excite phosphors that fill in the rest of the visible spectrum, but an alternative for decorative applications is separate red, green, and blue LEDs, which can be adjusted to produce a wide range of colors. One example is the interior lighting of the Boeing 787 Dreamliner jet, which changes color mix to relax passengers.

NASA plans to install RGB illumination in the International Space Station for another purpose: to help astronauts sleep better. Their natural circadian rhythm is disrupted in space, so NASA wants lights that change from a blue-rich blend to keep astronauts alert in the day to a red-rich blend that helps them relax at night.6 It's an idea that could find a broad range of other uses in our sleep-deprived society.

Outlook

Green laser diodes are growing up fast. Walter Burgess of Power Technology (Alexander, AR) reports that green diodes are already finding OEM applications in systems where human visibility is important. One example is outdoor pointing, where red laser-diode spots are not visible during the day. "Size, weight, and power are all factors" in picking green diodes over doubled neodymium, he says.

The company now offers packaged modules emitting up to 50 mW at nominal wavelengths of 510 or 520 nm, with the longer wavelength priced at a premium. Burgess says his customers want even longer wavelengths, close to the 550 nm peak of daytime vision.

We're not there yet, but there's lots of interest. Competition is so intense that some developers of green nitride lasers didn't want to tip their hands by talking to a reporter. Hitachi's Central Research Laboratory (Tokyo, Japan) has produced 50 mW CW at room temperature from BeZnCdSe laser diodes at 536 nm, although lifetimes of the II-VI compounds have been a serious problem.7 And a last-minute wild card is the demonstration of bright yellow emission from InGaN made by a new process (see "New plasma process produces bright yellow LEDs").

REFERENCES

1. D. Sizov, R. Bhat, and C.-E. Zah, "Gallium Indium Nitride-Based Green Lasers," J. Lightwave Technol., 30, 679–699 (Mar. 1, 2012).

2. U. Strauss et al., "Pros and cons of green InGaN laser on c-plane GaN," physica status solidi (b), 248, 652–657 (March 2011); doi:10.1002/pssb.201046299.

3. S. Takagi et al., "High-Power (over 100mW) Green Laser Diodes on Semipolar f20_21g GaN Substrates Operating at Wavelengths beyond 530nm," Appl. Phys.Expr., 5, 082102 (2012); http://dx.doi.org/10.1143/APEX.5.082102.

4. K. Yanashima et al., "Long-Lifetime True Green Laser Diodes with Output Power over 50mW above 525nm Grown on Semipolar f20_21g GaN Substrates," Appl. Phys.Expr., 5, 082103 (2012); http://dx.doi.org/10.1143/APEX.5.082103.

5. U. Strauss et al., "More optical output power of visible nitride laser diodes," 9th Intl. Symp. on Semicon. Light Emitting Devices—Program & Abstract, paper O3A00, Berlin, Germany (July 22–27, 2012); http://issled2012.org/complete.pdf.

6. G.C. Brainard et al., "Solid-state lighting for the International Space Station: Tests of visual performance and melatonin regulation," Acta Astronautica (2012); http://dx.doi.org/10.1016/j.actaastro.2012.04.019.

7. S. Fujisaki et al., "High-Power Continuous-Wave Operation of BeZnCdSe Single-Quantum-Well Green Laser Diodes," Appl. Phys.Expr., 5, 062101 (2012); doi:10.1143/APEX.5.062101.

New plasma process produces bright yellow LEDs

Yellow is a hard part of the spectrum for semiconductor sources to reach, so no one had paid much attention to that part of the spectrum. Then over the summer a small Canadian company called Meaglow (Thunder Bay, ON, Canada) tested a new plasma-based growth process on InGaN mixture with a bandgap in the yellow."We made a very simple p-n junction, and thought we would be lucky to see anything," says Meaglow founder Scott Butcher. The structure lacks quantum wells and other optimization. He was very surprised to see the bright yellow emission shown in the photograph. Efforts to understand the results are underway. More details are available at http://bit.ly/Ts53T3.

There's been no great clamor for yellow sources, although yellow lasers are used in medicine, and yellow LEDs could improve color in solid-state lighting. But this unexpected bright light could illuminate new possibilities.