Applied Scientific Instrumentation (ASI; Eugene, OR) has developed a continuous reflective-interface sample-placement (CRISP) system that mostly eliminates focus drift in high-power microscopes by sensing minute changes between the objective lens and the specimen’s cover slip, and then providing a feedback signal to any of ASI’s focus controllers or existing piezoelectric-based focusing devices such as their rapid automated modular microscope (RAMM) system. The CRISP system allows a specimen to remain accurately focused for hours at a time with a focus accuracy of 5% of the objective depth of focus, and will also maintain focus while scanning through a sample.

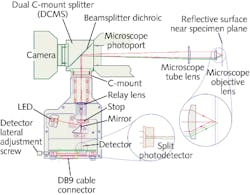

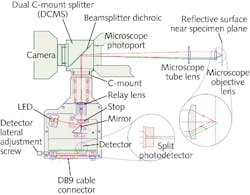

With optical, electronic, and mechanical components housed in a compact package, CRISP injects IR LED illumination into the microscope, captures the beam reflected from the specimen slide or cover slip, and routes the reflected beam onto a position-sensitive detector (PSD). The signal from the PSD is conditioned by an amplifier circuit in the MS2000 controller and used as the feedback signal for z-axis control. The CRISP module also adapts to the C-mount port of nearly all microscopes with a dual-C-mount splitter (DCMS)-based beamsplitter. Contact John Zemek at[email protected].