A light source that operates via so-called Dicke superradiance has been created by scientists at the University of Cambridge (Cambridge, England) and the PN Lebedev Physical Institute (Moscow, Russia); the two-section gallium nitride (GaN)-based laser diode produces 1.4 ps optical pulses at a 10 MHz repetition rate and a 408 nm wavelength. Superradiance is an alternative to Q-switching or modelocking for producing ultrafast pulses. Previously achieved only in near-IR laser diodes emitting between 800 and 1580 nm, superradiance requires a very high density of electrons and holes, as well as the presence of a resonant electromagnetic field to help in pairing the electrons and holes.

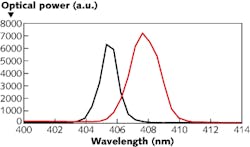

The researchers started with a commercially available, single-transverse-mode violet laser diode from Sharp Corp. (Osaka, Japan); after uncapping the laser, they used focused-ion-beam etching to modify the p-contact metallization, creating a two-section device with an absorber section and a gain section. The gain section was driven at room temperature with electrical pulses that were several nanoseconds long. At a reverse bias of -3.7 V, superradiance occurred, producing peak optical powers greater than 2.5 W and pulse lengths almost four orders of magnitude shorter than the electrical pulse length. Compared to the emission spectrum of the device operated at a lower reverse bias that produced gain-switched pulses (black), the superradiant pulses (red) showed a red shift of 2.7 nm. Contact Ian White at [email protected].