Queen’s University (Kingston, ON, Canada) physicist and principal investigator James Fraser and doctoral candidate Paul Webster have solved a significant problem inherent in the use of lasers in automated industrial welding, drilling, and machining: The inability to effectively monitor the depth and quality of laser welds on the fly. Their new inline coherent imaging (ICI) technique is a novel high-speed inline diagnostic system that can measure on-the-fly laser weld penetration depth with micron precision and microsecond speeds.

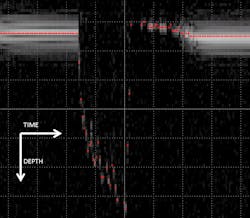

The all-optical depth measurement is made by axially combining a typically 850 nm sensing light-source beam (and the laser-machining beam along the same path and combining the resulting backscattered light from the weld pool with reference light in an interferometer. The resulting measured interference pattern is analyzed spectrally and the weld-depth data are computed from the absolute path mismatch between the two interferometer arms. Unlike triangulation approaches, ICI is able to obtain depth information from deep geometries without bulky optics. Since the detection is coherent and spectrally isolated from the welding beam, ICI unaffected by intense scatter, blackbody emissions, and momentary signal loss due to material expulsion. Queen’s University’s PARTEQ Innovations plans to commercialize the technology. Contact Stephen K. Adolph at [email protected].