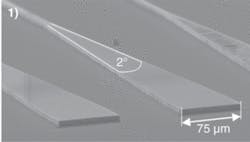

Although mid- to far-infrared quantum-cascade (QC) lasers are ideal for gas sensing, free-space optical communications, and imaging, their high beam divergence (typically about 48º for ridge-waveguide devices) can be a limiting factor for resolution and efficiency. To significantly reduce this divergence, researchers at the Universität Würzburg (Würzburg, Germany) created lasers with an index-guided tapered gain section using a unique processing method.

In the growth process, 35 active periods on an indium phosphide (InP) substrate are embedded in tapered structures in an indium gallium arsenide waveguide core facing the substrate and adjacent to a 2-µm-thick InP top cladding. This approach differs not in the QC growth stage, but in the processing of the grown structure: instead of just evaporating a tapered contact on the grown structure (as in the typical gain-guided approach for semiconductor diode lasers), the researchers completely etch through the grown layers leaving a tapered-shaped device. Because they etch through the whole active region and achieve a semiconductor/air interface, current spreading does not take place and divergence is minimized. The 200 mW tapered QC lasers have a horizontal beam divergence of only 6.6º in the single-lobe far field at a wavelength of approximately 8.9 µm. Contact Julia Semmel at [email protected].